SureTap Hot Tapping Machines

The SureTap® range of proprietary hot tapping machines provide performance and reliability for critical, high-pressure tapping operations. Designed and built to incorporate industry-leading features, the SureTap range incorporates a double block and bleed sealing configuration, allowing taps to be performed safely on a wide range of pipeline materials and mediums, including use with sour (H2S) products. A positive retention pilot drill system has been incorporated to ensure robust securing and recovery of the cut pipeline coupon. As standard, all SureTap machines are suitable for onshore, topsides or subsea operations and are fully compatible with industry-standard tapping equipment; including the deployment and recovery of completion plugs.

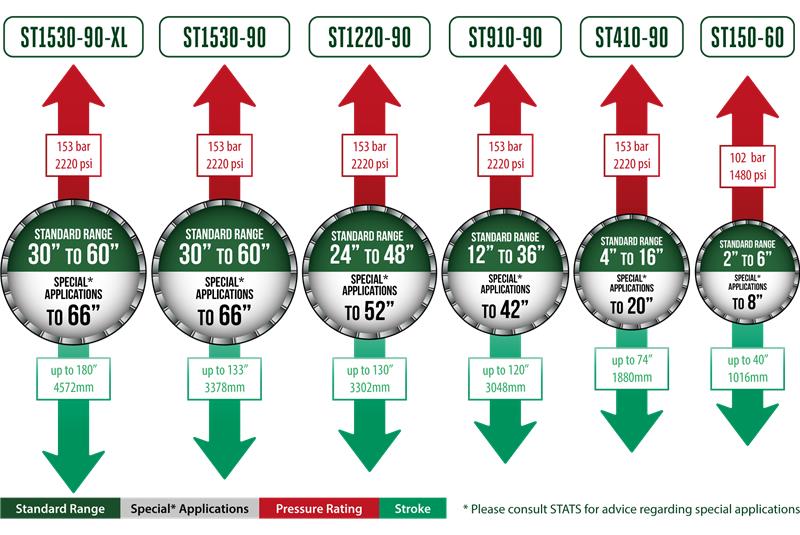

SureTap Range

ST1530-90 Hot Tapping Machines

- 30” – 60” (66”*) cutter size

- 153 bar / 2220 psi pressure rating

- Pressure class: ANSI Class 900

- Process fluid seal housing features dual seal configuration

- Positive retention pilot drill system for robust securing and recovery of the cut pipe coupon

- Pressure compensated feed system

- Variable speed and feed configuration

- Suitable for use with sour (H2S) products

- Subsea compatible

- Compatible with industry standard tapping equipment

- Capable of deploying and recovering completion plugs

- Dedicated transportation frame for secure shipping, storage and routine maintenance

- Dedicated workstation for ease of use and operator safety

- Power provided from a portable, custom hydraulic power unit (HPU)

*Please consult STATS for cuts up to 66"

ST1220-90 Hot Tapping Machines

- 24” – 48” (52”*) cutter size

- 153 bar / 2220 psi pressure rating

- Pressure class: ANSI Class 900

- Process fluid seal housing features dual seal configuration

- Positive retention pilot drill system for robust securing and recovery of the cut pipe coupon

- Pressure compensated feed system

- Variable speed and feed configuration

- Suitable for use with sour (H2S) products

- Subsea compatible

- Compatible with industry standard tapping equipment

- Capable of deploying and recovering completion plugs

- Dedicated transportation frame for secure shipping, storage and routine maintenance

- Dedicated workstation for ease of use and operator safety

- Power provided from a portable, custom hydraulic power unit (HPU)

*Please consult STATS for cuts up to 52"

ST910-90 Hot Tapping Machines

- 12” – 36” (42”*) cutter size

- 153 bar / 2220 psi pressure rating

- Pressure class: ANSI Class 900

- Process fluid seal housing features dual seal configuration

- Positive retention pilot drill system for robust securing and recovery of the cut pipe coupon

- Pressure compensated feed system

- Variable speed and feed configuration

- Suitable for use with sour (H2S) products

- Subsea compatible

- Compatible with industry standard tapping equipment

- Capable of deploying and recovering completion plugs

- Dedicated transportation frame for secure shipping, storage and routine maintenance

*Please consult STATS for cuts up to 42"

ST410-90 Hot Tapping Machines

- 4” – 16” (20”*) cutter size

- 153 bar / 2220 psi pressure rating

- Pressure class: ANSI Class 900

- Process fluid seal housing features dual seal configuration

- Positive retention pilot drill system for robust securing and recovery of the cut pipe coupon

- Pressure compensated feed system

- Variable speed and feed configuration

- Suitable for use with sour (H2S) products

- Subsea compatible

- Compatible with industry standard tapping equipment

- Capable of deploying and recovering completion plugs

- Dedicated transportation frame for secure shipping, storage and routine maintenance

*Please consult STATS for cuts up to 20"

ST150-60 Hot Tapping Machines

- 2” – 6” (8”*) cutter size

- 102.1 bar / 1481 psi pressure rating

- Pressure class: ANSI Class 600

- Variable speed and feed configuration

- Suitable for use with sour (H2S) products

- Subsea compatible

- Compatible with industry standard tapping equipment

- Capable of deploying and recovering completion plugs

- Dedicated transportation frame for secure shipping, storage and routine maintenance

*Please consult STATS for cuts up to 8"

Sizes below 2" can be conducted with third party machines.

Materials of Construction

The SureTap machines are manufactured from high quality materials to European or North American standards. All components used to contain pressurised process fluids are manufactured from pressure vessel grade materials (to ASTM or EN standards), impact tested at sub-zero temperatures and resistant to sulphide stress cracking (SSC).

Legislation, Codes & Directives

- ASME B16.5: Pipe flanges and flanged fittings

- ASME B31.3: Process piping

- ASME B31.4: Pipeline Transportation System for Liquid Hydrocarbons and Other Liquids

- ASME B31.8: Gas Transmission & Distribution Piping Systems

- ASME BPVC. Section VIII, Division 1: Design and Fabrication of Pressure Vessels

- ASME BPVC. Section VIII, Division 2: Alternative Rules

- NACE MR0175/ISO 15156-2: Petroleum and natural gas industries - Materials for use in H2S containing environments in oil and gas production

- EU directive 2006/42/EC: Machinery

- EU directive 97/23/EC: Pressure equipment

Related Resources

Subsea Mechanical Clamp and Hot Tap Tie-In

Contact Us

Terms & Conditions

Click on the links below to download a copy of our Terms and Conditions

Purchase Order Terms and Conditions

Terms and Conditions for Sale, Rental, and Services

For further information, please email: sales@statsgroup.com