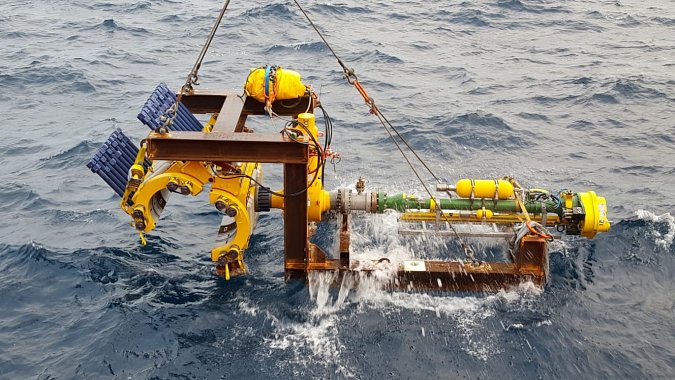

Subsea Hot Tap Clamp

STATS subsea Mechanical Hot Tapping clamps facilitate the connection of new branch pipework to existing infrastructure without the requirement for hyperbaric welding or pre-installed tees. Mechanical clamps are routinely used to provide a flanged off-take to enable hot tapping into an existing pipeline while under pressure and with no interruption to production. The clamps can also be utilised as an access point to deploy a temporary double block and bleed BISEP isolation, STATS proprietary line plugging technology.

Subsea mechanical clamps are routinely used to provide a flanged off-take to enable hot tapping into an existing pipeline while under pressure and with no interruption to production. The clamps can also be utilised as an access point to deploy a temporary double block and bleed BISEP isolation, STATS proprietary line plugging technology.

Mechanical Hot Tap Clamp Applications

- Tie-in or re-route of subsea pipeline infrastructure

- Subsea pipeline repair: hot tapping access point to deploy BISEP, double block and bleed line plugging technology

Key Features

- Designed to meet clients pipeline pressure and size requirements

- Dual seal design, independent activation of seals and locks

- Designed to be compatible with STATS BISEP line plugging technology

- Designed to withstand full pipe separation loads (full structural design)

- Hydrogenated Nitrile Butadiene Rubber (HNBR) seal supplied as standard, alternative sealing material available upon request

- DNV Design Review Certificate available upon request (optional item)

- Annulus test port allows a pressure test between the dual seal arrangement

- Designed for compatibility with a wide range of pipe materials including carbon steel and stainless steel as standard, duplex available on request

- External grip assembly applies even linear and circumferential grip load around the host pipe, eliminating localised material deformity and localised stress fractures.

- Easily installed and commissioned by divers with basic training

- External grip, lock and seal assemblies eliminate possible flow disturbance and turbulence

Applicable Standards & Specifications

- DNVGL-ST-F101 Submarine Pipeline Systems

- ASME Boiler and Pressure Vessel Code, Section VIII, Div 2API 5L, Specification for Line Pipe

- ASME B16.5, Pipe Flanges and Flanged Fittings

- ASME B31.8, Gas Transmission and Distribution Systems

- ASME B31.4, Pipeline Transportation Systems for Liquid Hydrocarbons

- API 6H, Specification on End Closures, Connectors and Swivels

- External coated in accordance with Norsok M501 System 7

Related Resources

Subsea Mechanical Clamp and Hot Tap Tie-In

Subsea Mechanical Hot Tap Fittings

DownloadContact Us

Terms & Conditions

Click on the links below to download a copy of our Terms and Conditions

Purchase Order Terms and Conditions

Terms and Conditions for Sale, Rental, and Services

For further information, please email: sales@statsgroup.com