Mechanical Pipe Connectors

A Cost-Effective Weldless Solution For Tie-Ins And Permanent Repairs

Avoid hot work and reduce out of service time.

Our DNV type approved mechanical pipe connectors eliminate the need for hot work, and can be installed without specialist tools or activation equipment – minimising the duration and cost of maintenance projects. STATS mechanical connectors are also available for titanium pipelines.

0.75" – 60" Size Range

50 bar / 725 psi As Standard

425 Bar / 6164 psi + Available on Request

DNV Type Approval

100% Leak Free Service History

Traditional methods of pipe repair are effective, but costly and difficult to facilitate. Hot work often necessitates a halt in production, the shut down of process equipment and the establishment of a safe welding environment. Not to mention the expense involved in bringing in a team of highly-trained specialists.

Key Benefits

- Increases site safety by avoiding hotwork

- Reduces downtime compared with welding operation

- Reduces maintenance costs by eliminating requirement for welding personnel and equipment

- No specialist installation tools required – standard bolting

- Integrated test port eliminates requirement for additional tooling

- External lock and seal assembly avoids flow restriction and swaging of parent pipe

- Qualified and DNV type-approved for installation on titanium pipework.

- Wide range of pipe materials including carbon steel, stainless steel, duplex, super duplex, CuNi and Titanium.

Case Study - 18" Connectors For Norwegian Oil Terminal

STATS Group supplied two 18" mechanical connectors for a pipe replacement project – enabling essential maintenance to be carried out while the plant was operating.

Webinar - Maximising Shutdown Efficiency

Learn how the execution of maintenance activities can be safely conducted by removing the requirement for welding and the associated risks of hot work.

Cold work solutions like mechanical pipe connectors are more cost-effective and significantly reduce the duration of maintenance projects, making them a popular choice for pipe repairs, tie ins and the capping of redundant pipe work.

Conventional connector designs have some disadvantages, requiring specialised installation and activation tools that have to be leased from a provider, and shipped to location before you can carry out maintenance work. This can become costly if projects are delayed or overrun.

Many mechanical pipe connectors also work by deforming pipe to create a strong bond and leak-tight seal. This is technically safe but creates defects that can cause turbulence and increase the risk of high corrosion rates.

To ensure that our clients have access to a reliable, efficient and cost-effective cold work solution, STATS has developed a suite of mechanical pipe connectors that don't require specialist tools, and don't deform pipework to create a leak-tight seal.

When these mechanical pipe connectors are activated, the external grip assembly applies even pressure over a large area, preventing deformation and eliminating the risk of localised stress fractures.

The external lock and seal assembly prevents turbulence and ensures that flow is preserved, while dual fire-safe graphite seals ensure a proven 100% leak-free connection and a minimum design life of 20 years.

Our mechanical pipe connectors slide over bare pipe ends and are activated by applying torque to a bolt arrangement that activated the external locks. Fitting can be done by STATS personnel, or we can train your own staff to fit them – eliminating the need to accommodate and pay for external teams. Suitable mechanical connectors could then be kept on-hand as part of an emergency contingency plan, or bought as-needed to support maintenance projects.

Minimise downtime reduce maintenance outlay

Every second of preventable downtime impacts the productivity and profitability of your operation, which is why our mechanical connectors are designed to be quick and easy to install.

STATS Group mechanical connectors are suitable for topside, terminal, FPSO or subsea installation, and compatible with all process streams. They are also available to suit a wide range of pipe materials including carbon steel, stainless steel, duplex, super duplex and CuNi.

Lightweight, but robust enough to provide equivalent or greater design criteria than the host pipework, they slide in place and lock using a simple bolted installation procedure – quickly providing maintenance-free mechanical pipe connections in accordance with API specification 6H and certified fire-safe to API 6FA.

Our mechanical pipe connectors are built to last, with a design strength verified in accordance with ASME B31.3, DNV approval for permanent pipeline repairs and a minimum design life of 20 years.

We use dual graphite seals for onshore or topside applications where fireproofing is a necessity, and durable dual elastomer seals for subsea repairs, tie ins or capping projects.

All connectors also feature an integrated seal verification port that provides access to the annulus void between the seals – enabling you to carry out a leak test once your connector is fully installed.

If required, there is also the option to fit a double block and bleed valve to the seal verification port so that you can periodically monitor the integrity of the connection, as part of a routine maintenance or inspection programme.

Our mechanical connectors demand minimal pipework preparation and have been fitted to a wide variety of piping systems. More importantly, we're proud to report that our mechanical pipe connectors have a 100% leak-free service history and continue to offer fantastic value for money to clients operating across the globe.

Onshore and Topsides

Mechanical Pipe Connectors

A quick, efficient and cost-effective alternative to hot work solutions, our standard mechanical pipe connectors are available in a range of sizes from 1" to 36" as standard, with larger variants up to 60" available on request. We supply connectors with a flanged outlet for connecting plain-end pipe to a pre-flanged termination, couplings to connect plain-end pipe to plain-end pipe and end caps for capping plain-end redundant pipe work.

Codes & Standards

- Connectors and couplings conform to ISO 21329

- Compliant with DNVOS-F101:2012

- Compliant with DNVRP-F113:2007

- Fire tested to API 6 FA

- Designed in accordance with API 6H requirements

- Strength verified in accordance with ASME B31.3

- Designed to fit standard pipe specifications

Weldless Solution Minimise Downtime & Costs

Onshore and Topsides

Mechanical Pipe Connectors for Titanium Pipelines

A Safer, Faster Alternative to Welding.

Titanium pipelines offer superior corrosion resistance, but when it comes to repairs or modifications, welding is expensive, time-consuming, and risky. STATS Mechanical Connectors provide a cold-work solution - delivering fast, permanent, and leak-free connections without the need for welding or hot work.

Connectors For Titanium Pipelines

- Dual Fire-Safe Graphite Seals: Ensures a 100% leak-free, permanent connection.

- Simple Installation: Slide over bare pipe end, activated with standard bolting, no specialist tools.

- Routine Maintenance/Inspection: Optional double block and bleed valve fitted to seal verification port for periodic integrity checks.

-

1" to 12" Type Approved

-

#150 & #300 Pressure Ratings

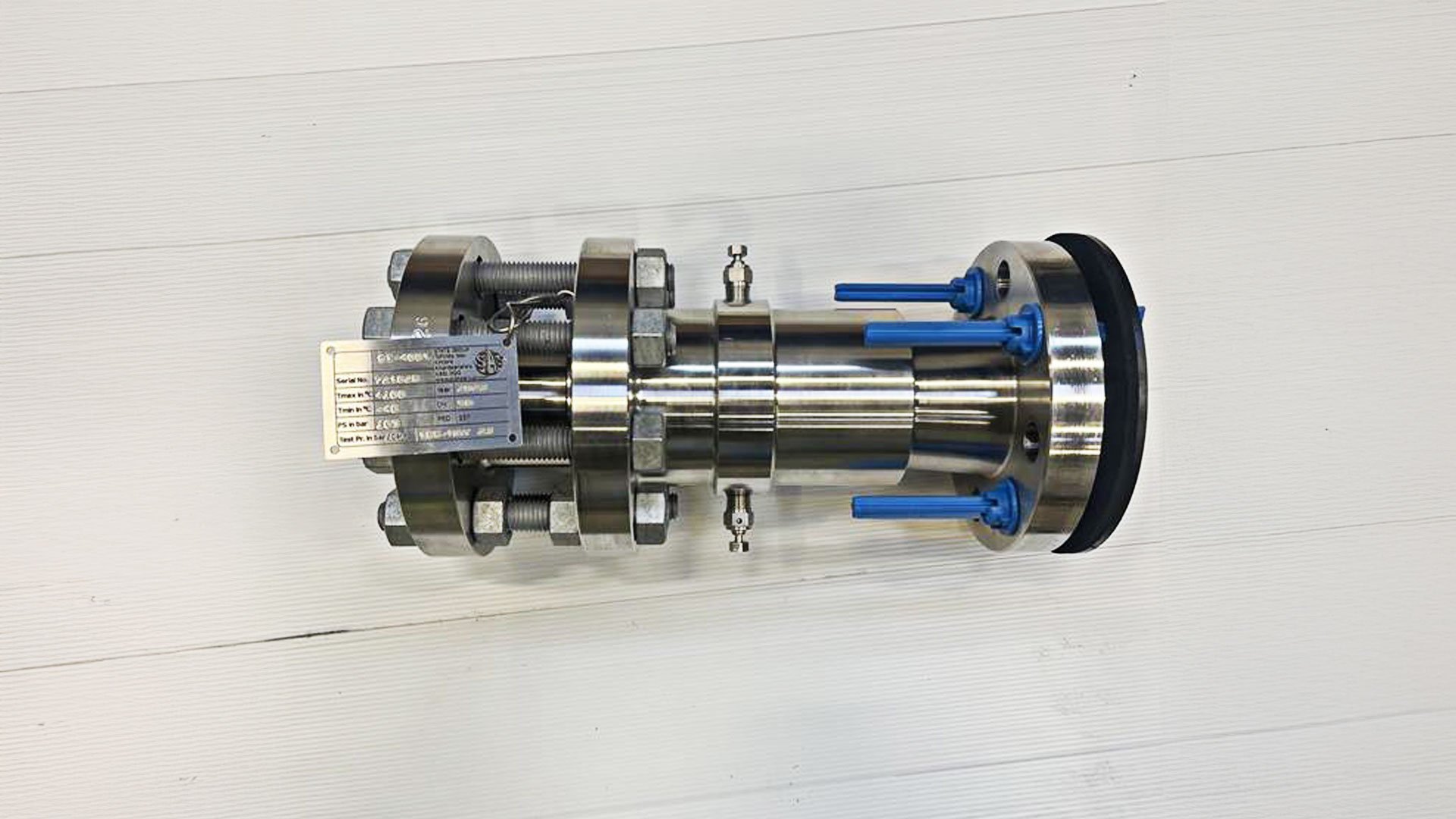

2" #600 Connector

STATS mechanical connectors are DNV type approved for the use on titanium pipelines, offering the energy industry a safe and efficient alternative to welding.

The Connectors cover a size range from 0.75” to 60” with various pressure ratings and are available in connector, coupling and end-cap configurations.

Unlike existing alternatives that are limited in size range or lack proper testing capabilities, these connectors provide a reliable, permanent connection with an integrated test port - enabling a leak test to be performed once the connector is fully installed – negating the need for additional joint testers.

End Cap for capping plain-end pipework

Flanged outlet for connecting plain-end pipe to a pre-flanged termination

Coupling for connecting plain-end pipe to plain-end pipe

Subsea

SureConnect Subsea Mechanical Connectors

Designed to eliminate the need for hyperbaric welding, SureConnect® subsea mechanical connectors are equally easy to commission and install. You can learn more about our range of subsea mechanical connectors here.

Codes & Standards

- DNVGL-ST-F101 Submarine Pipeline Systems

- ASME BPVC Section VIII, Div 2

- API 5L

- ASME B16.5

- ASME B31.8

- ASME B31.4

- API 6H on End Closures, Connectors and Swivels

- Norsok M501 System

Avoid hyperbaric welding Tie-In, Repair or End Cap