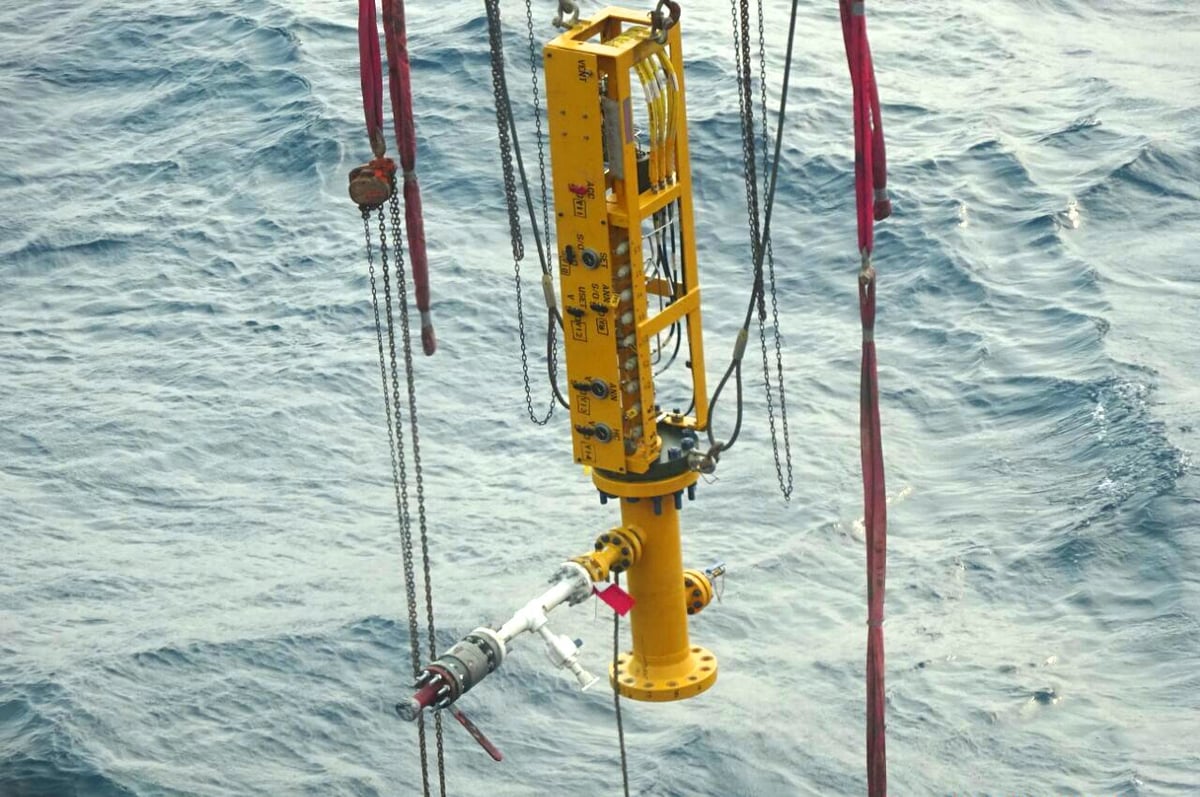

Subsea BISEP Line Plugging

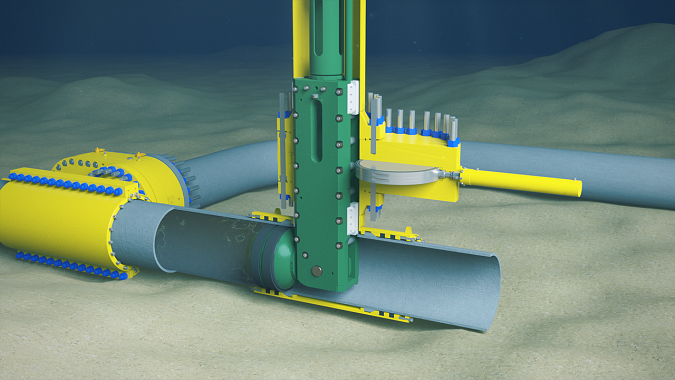

The BISEP® provides the highest level of hot tap installed pipeline isolation in the industry. Complying with all relevant subsea isolation guidelines, the BISEP ensures safe worksite conditions for divers and the environment from breaking of containment to reinstatement.

The BISEP is the only hot tap installed double block isolation tool that satisfies the design criteria for DNV Type Approval for Pipeline Isolation Plugs. The design criteria satisfies the requirements for Pipeline Isolation Plugs to provide dual seal and isolation in accordance with Offshore Standards: DNV-OS-F101 (Submarine Pipeline Systems) and recommended Practices: DNV-RP-F113 (Subsea Pipeline Repair) and is code compliant with: ASME BPVC Section VIII, Division 2.

The use of the BISEP provides a high integrity, temporary subsea isolation that offers operators significant benefits by avoiding the need to decommission and then recommission the entire subsea infrastructure.

Specification

Size

3”– 56”

Pressure

up to 153 bar / 2220 psi

Verification

DNV Type Approval

Temperature

-20°C to 100°C

Applications

- Subsea Isolation Valve installation, replacement / repair

- Pipeline tie-in / re-routing

- Sectional pipeline replacement / repair

- Riser replacement / repair

- Pressure testing, leak detection of risers or repaired pipelines

- Isolation of subsea manifolds or skids for repair or replacement

- Dead leg removal

- Platform / pipeline abandonment, bypass, or decommissioning

Key Features

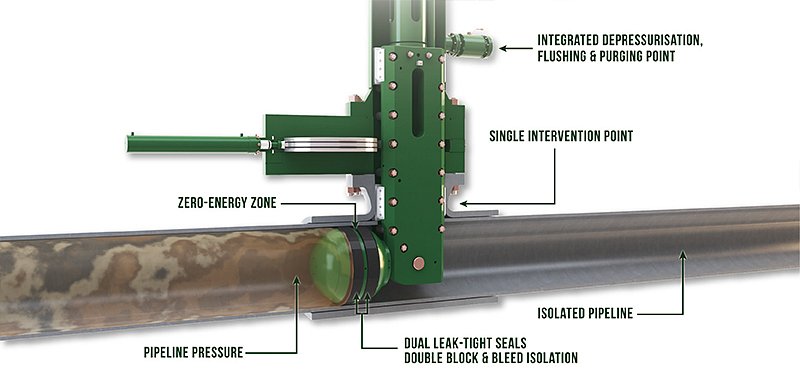

- Double block and bleed isolation compliant with subsea industry isolation best practice. (DNV-RP-F113 Pipeline Subsea Repair – recommended practice)

- Monitored dual seal annulus void proves seal integrity before and during intervention work

- Isolation integrity continuously monitored through annulus void, hydraulic set circuit and body vents

- Seal annulus void provides a Zero-Energy Zone (minimal volume x pressure)

- In bad weather, enhanced actuation system allows long-term disconnection from support vessel

- Isolation remains stable and leak-tight even with significantly fluctuating pipeline pressures

- The BISEP design ensures diver safety in the event of negative and positive pipeline differential pressures

- Plugging head designed to take pressure in the reverse direction. This allows pressure higher than the isolated pipeline pressure to be applied to the reinstated pipework (as a pressure test or purge) prior to removing the BISEP.

Related Resources

Subsea Repair Scenarios of Damaged Pipelines

28" Subsea Pipeline Isolation & Repair, Yacheng Pipeline, China

Emergency Pipeline Repair Isolation Systems

10" Subsea Hot Tapping and Plugging, Gulf of Mexico

Contact Us

Terms & Conditions

Terms of sale

Where STATS Group Terms of Sale are referenced from and including the 10th July 2025: Download PDF

Where STATS Group Terms of Sale are referenced prior to the 10th July 2025: Download PDF

Terms of purchase

For Purchase Orders issued from and including the 10th July 2025: Download PDF

For Purchase Orders issued prior to the 10th July 2025: Download PDF