Subsea Pipeline Isolation Services

Turnkey Subsea Pipeline Isolation Services

We deliver subsea pipeline isolations as an integrated turnkey solution. Using our field-proven technologies, and rigorous standardised procedures, our highly trained workforce deliver robust solutions safely and on time.

FIELD-PROVEN Technology

INTEGRATED Procedures

HIGHLY TRAINED teams

REGIONAL capability

Traditional subsea pipeline isolation services can involve the use of multiple technologies, different company procedures, and a range of contract staff and equipment, deployed from all over the world.

STATS offers a full turnkey solution using our field-proven technologies, combined with a highly trained team, integrated procedures, regional delivery hubs, supported by expert engineers.

KEY TAKEAWAYS

- Turnkey solutions for subsea pipeline isolations

- The best field-proven technology for safe isolations, providing one tooling solution

- Integrated procedures, developed to the highest standards, underpinned by consistent risk assessments

- Operators are robustly trained to use all of our technology, supervised by competent and qualified technicians

- Supervisors/operators are trained on all our technologies, reducing vessel bed-space requirements

- Regional delivery hubs with manufacturing capability and established, proven local supply chains, supporting the local economy

- Design engineering capability in our regional hubs, and internationally spread R&D

- Supported by a full engineering service, guaranteeing standards and quality

Case Study - Live 28" Subsea Gas Pipeline Repair

Isolated repair on anchor-damaged subsea gas pipeline in the South China Sea, ensures quick and safe return to service.

Case Study - 8" Subsea Pipeline Repair Without Depressurisation

8" live subsea gas pipeline in Gulf of Thailand repaired. Use of BISEPs ensured diver safety, uninterrupted production and minimised environmental damage.

Pipeline isolation is a key requirement for safe and efficient maintenance, modification or repair of oil and gas subsea pipelines.

90% of our customers engage with us to provide the full service for subsea pipeline isolations, but you can pick and choose the elements you need as part of this service.

Remote Isolation With the Tecno Plug® System

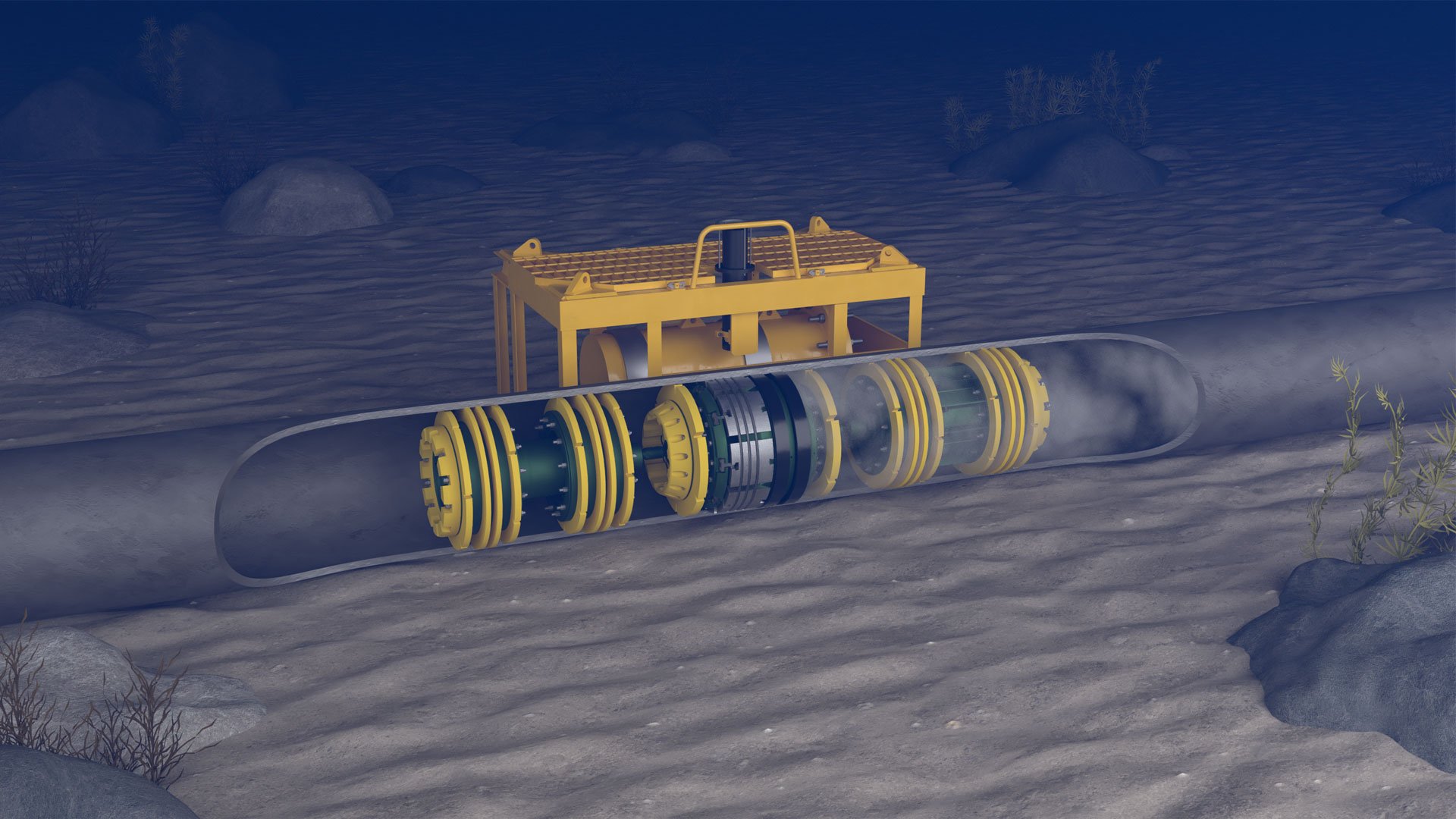

The subsea Remote Tecno Plug® system is a piggable, remote-controlled, tetherless isolation tool. It provides a fail-safe double block and monitor isolation of pressurised subsea pipelines while the system remains live and at operating pressure.

This DNV Type Approved plug uses a dual seal configuration providing an annulus between seals, which can be pressure tested to verify both seals are leak-tight before maintenance work is carried out. Through-wall communication is achieved using an extremely low frequency (ELF) inductive system for reliable tracking and accurate positioning. Remote control modules can be made available for use in a Zone 2 environment, and antenna and field cable are available for use in Zone 1 environments.

Comprehensive Hot Tapping and Line Stopping Solutions

We also have hot tapping and line stopping technology, BISEP®, compliant with DNV Type Approval for submarine pipeline systems, subsea pipeline repairs, as well as ASME BPVC Section VIII, Division 2. This is a safe, reliable and proven solution for subsea temporary line stopping.

Our SureTap® range of proprietary hot tapping machines provides performance and reliability for critical, high-pressure tapping operations. Designed to establish a reliable connection to existing piping or pressure vessels without interrupting operations, SureTap machines are manufactured to meet the highest ASTM and EN standards.

Integrated Subsea Tooling and Services

The full range of tools, all suitable and proven for subsea operation, include subsea abandonment plugs, mechanical pipe connectors, repair clamps, hot tap clamps, temporary launcher/receiver, pipe lifting and retrieval tools.

Our technology and services are completely integrated, providing the benefit of reducing delays and liabilities that can be incurred when using third-party equipment.

The right people locally

At the heart of our operations are our people. We strategically recruit individuals for their potential, then empower our teams through comprehensive development programmes designed to cultivate their skills and expertise. This commitment to our workforce is evident in the longevity of our staff, with many team members staying with us for 10 years or more.

Highly trained supervisors and operators, in the right place, using standardised risk assessments and procedures, deploying superior technology.

This dedication to development continues throughout their careers. We have a robust onboarding process for all new hires, regardless of their global location. This is then enhanced with in-region training at our regional hubs, delivered by qualified experts and supported by experienced on-the-job supervision.

The same individuals who train our teams in the regional hubs also provide on-site supervision, ensuring continuity of experience and bringing real-world insights directly into the training environment.

Our training is robust and exacting, following a strict programme of staged levels and competency testing. Operators are trained in the use of all our technologies against integrated procedures, not just equipment-specific ones, ensuring consistent and exacting standards across all operations. This integrated approach, covering everything from clamping to hot tapping, has been consistently cited by our clients as a significant benefit, reducing complexity and improving efficiency while upholding the highest safety standards.

Delivering Value

For the Benefit of Every Client

Highly trained supervisors and operators, in the right place, using standardised risk assessments and procedures, deploying superior technology.

We understand that not all jobs are standard. For unique situations with potential unintended consequences, we deploy our Engineering Assessment teams. They conduct detailed surveys and propose tailored solutions, whether that involves custom-designed equipment or revised procedures, always maintaining our high, consistent standards.

Key Advantages

- Optimised resources - Fewer operators are needed when we deploy our technology

- Reduced errors - Clear communication and streamlined equipment management mean fewer mistakes

- Integrated monitoring - Our operators also handle monitoring requirements, easing the burden on your own teams

Subsea Connector Testing

Regional hubs

Local capability, global reach

Our regional hubs are pivotal to our strategy, combining local manufacturing with an emphasis on training local personnel.

This approach allows us to provide cost-competitive and highly responsive services (subject to local labour laws). It also significantly benefits local economies and reduces the environmental impact of our operations.

These major regional hubs are fully equipped with design, engineering, and manufacturing capabilities, further bolstered by qualified local supply chains.

Local Everywhere

Instead of flying people and equipment all over the world, we've set up fully-functional bases in nine strategic locations. These bases enable us to employ local technicians, work with local manufacturers, and invest in local economies. They're a significant investment, but our regional bases are key to delivering the best possible service for our clients - and minimising the environmental impact of our work.

Related Products

Subsea Remote Tecno Plug

For fail-safe double block and monitor isolation of pressurised subsea pipelines while the system remains live and at operating pressure.

Subsea BISEP

Complies with all relevant subsea isolation guidelines. Ensures safe worksite conditions for divers from breaking of containment to reinstatement.

Subsea Abandonment Plugs

Temporary or permanent cap to terminate open pipe ends. Robust isolation barrier prevents seawater ingress or residual hydrocarbon escape.

Subsea Temporary Launcher Receiver

Flangeless subsea launcher can be efficiently lowered to the seabed and attached to any open pipe end without the need for a flanged connection or hyperbaric welding.