Emergency Pipeline Repair Systems

Have You Got A Deployment-Ready Emergency Pipeline Repair System?

Ensure energy security and reduce out of service time

Our emergency pipeline repair systems combine the procedures, processes, equipment and personnel needed to minimise unexpected downtime and protect your operation from unnecessary risk.

Inline Isolation Plugs

Hot Tapping & Plugging

Mechanical Clamps & Connectors

Designed To Pipeline Specification

Equipment & Manpower

Unfortunately, pipelines can (and do) get damaged on a regular basis. Corrosion, fatigue, stress cracking, ground movement, mechanical damage, sabotage and a whole host of additional risks threaten the integrity of your pipelines every day. Lack of pipeline specific equipment, pre-engineered procedures and suitable arrangements for an unplanned emergency repair will result in excessive downtime, which will be prohibitively expensive.

Developing the necessary emergency repair procedures, investing in tooling and equipment, and having experienced manpower to call on when needed to carry out an emergency repair will ensure downtime is minimised, should an emergency repair become necessary.

Case Study - Isolation EPRS North Field Qatar

STATS Group were awarded in excess of $10 million (£6.5 million) for a ten year contract with a major LNG operator in the Middle East.

Webinar - Preparing For A Pipeline Incident

Learn about pipeline damage scenarios and emergency repair options in this one hour webinar, presented our VP of Technical Assurance.

We have developed fully-formed emergency pipeline repair systems (EPRS) for many operators across the globe, giving them peace of mind that should the unthinkable happen, they are properly prepared to respond rapidly to an emergency repair. Drawing on 25+ years of operational experience and collaborating with the client teams and other involved parties, we can create contingency plans, isolation and repair procedures for all foreseeable repair scenarios, and manufacture the long lead, pipeline specific equipment needed to carry out all types of emergency pipeline repair.

This includes procedures and equipment needed to repair or replace unpiggable pipeline defects, in some cases while production is maintained or returned to service ahead of the final repair, significantly reducing out-of-service times and minimising environmental impact.

Mitigate Risk Minimise stress

Unplanned incidents can wreak havoc on production schedules, and seriously impact the profitability of your operation. Assuming you have minimal mitigation in place, for a large diameter subsea pipeline it could take up to a year to fully restore pipeline integrity.

If you don't have the correct equipment to hand, or the right processes in place, it could take more than a year to return a subsea pipeline to service.

These lead times are further increased if the section of pipe in question has an unpiggable defect and/or needs to be fully removed and replaced.

Without double block and bleed isolation tools, you have to decommission the damaged pipeline to allow safe removal, and then recommission (leak test and dewater) the pipeline after repair work had been completed. In many cases, these processes account for approx. 60% of your total downtime.

A basic contingency plan and strategic investment in products with a long-lead time, like large forgings for clamps, mechanical connectors, or replacement pipe can reduce downtime to six to eight months.

Investing in an asset-specific emergency pipeline repair system, including detailed procedures for potential repair scenarios, all the necessary equipment, and specialised pipeline isolation tools will bring pipeline out of service times down significantly, and in the case of subsea pipelines to less than 100 days.

Understanding The Risks

Example Pipeline Damage Incidents

As assets age, the risk of catastrophic failure increases. Since 2007, there have been several major pipeline damage incidents. Most of these incidents took more than 12 months to resolve and cost operators millions of pounds per day in lost production.

Large Diameter Pipeline Incidents:

- 36” CATS trunk line

- 26” Kvitebjorn line

- 2 off 24” North Africa lines

- 30” ADMA oil export line

- 20” and 26” Trans-Med. lines

A comprehensive solution

Our Emergency Pipeline Repair Systems Explained

Combining our engineering expertise with an array of field-proven equipment, we create asset-specific emergency pipeline repair systems (EPRS) that ensure you and your team are prepared to deal with any type of pipeline incident.

Our Emergency Pipeline repair systems often include:

- Tecno Plug® inline isolation tools

- BISEP® hot tap installed line stopping tools

- SureTap® hot tapping machines

- Mechanical Connectors

- Pipeline repair clamps

- Pipeline launchers & Receivers

-

Double Block Isolation Tools

-

Mechanical Clamps & Connectors

-

DNV Type Approved Equipment

Industry-leading equipment Kept in a state of constant readiness

A proven process

Our approach to contingency planning

When asked to prepare an EPRS, we use a proven process to ensure that every eventuality is accounted for. This process starts with a detailed engineering assessment, and covers everything from the manufacture of equipment through to the maintenance of your EPRS package.

Our EPRS Process In Full:

- Carry out engineering assessment

- Profile potential repair scenarios

- Develop detailed procedures

- Design and manufacture equipment

- Storage and maintenance

All EPRS equipment will be kept in a state of constant readiness for emergency deployment including the supply of personnel to operate and deploy the equipment.

Importantly, we will put in place a contract for the long term maintenance and refurbishment of all EPRS equipment to ensure that it's always ready for immediate deployment.

Where larger or state-owned operators have a need to manage their EPRS inventory in-house, we can also provide call-out services to carry out routine maintenance and refurbishment work.

Operators and Tier 1 contractors around the world depend on us to supply and maintain comprehensive emergency pipeline repair systems that can be deployed at a moment's notice. Ensuring energy security and reducing out of service time should an unplanned incident take place.

Leveraging Field-Proven Pipeline Repair Equipment

We recognise that each EPRS implementation requires an element of custom engineering design and development. However, we also draw on an extensive range of field proven technologies to ensure full provision.

Below are the details of key products we provide as part of an emergency pipeline repair system.

Tecno Plug Isolation Tool

The Tecno Plug® provides fail-safe double block and bleed isolation of pressurised pipelines while the system remains live and at operating pressure. Dual seals provide a zero-energy zone to enable maintenance work on pressurised systems to be carried out safely and efficiently.

Subsea BISEP Plugging Tool

The BISEP® when deployed subsea provides the highest level of hot tap installed pipeline isolation in the industry. Complying with all relevant subsea isolation guidelines, the BISEP ensures safe worksite conditions for divers from breaking containment to reinstatement.

SureTap Hot Tapping Machines

The SureTap® range of proprietary subsea hot tapping machines provide performance and reliability for critical, high pressure tapping operations. Designed and built to incorporate industry leading features allowing taps to be performed safely on a wide range of pipeline materials and mediums, including use with sour (H2S) products.

Mechanical Pipe Connectors

Type Approved mechanical pipe connectors provide a cold-work solution, removing the associated risks of welding. Quick and efficient to install, this permanent solution significantly reduces maintenance duration and provides a cost-effective solution for piping repair, tie-in or capping of redundant pipework.

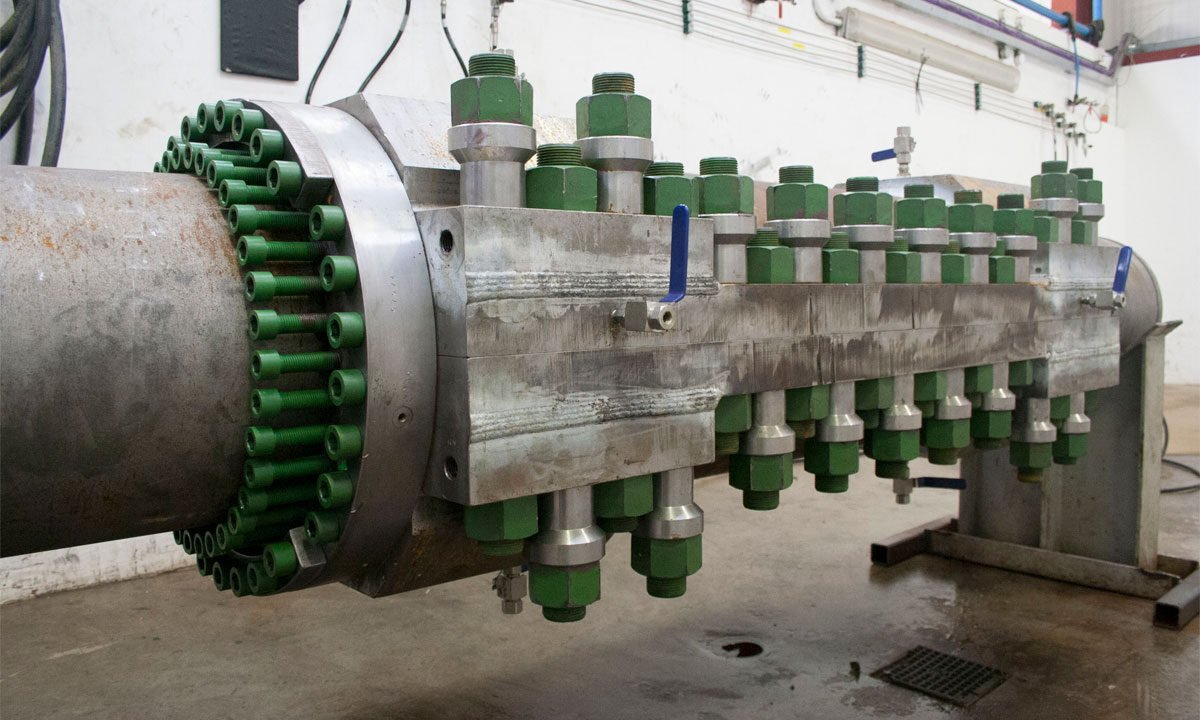

Pipeline Repair Clamps

Pipeline Repair Clamps are designed to be installed on damaged or leaking pipework, encapsulating the defect within the clamp body and regaining pressure integrity through mechanical seals and / or locks engaging on the sound parent pipe.

Pipeline Retrieval Tool

Pipeline Retrieval Tools facilitate the laydown or recovery of subsea pipelines and are designed for lifting large diameter pipe and heavy loads.

Local Everywhere

Instead of flying people and equipment all over the world, we've set up fully-functional bases in nine strategic locations. These bases enable us to employ local technicians, work with local manufacturers, and invest in local economies. They're a significant investment, but our regional bases are key to delivering the best possible service for our clients - and minimising the environmental impact of our work.