Bi-Stop temporary line plugging system

High Integrity Isolation Tools For Small-Bore Pipework

Cost-effective isolation that removes the need for shutdowns and outages

Our market-leading, small-bore isolation tool enables you to carry out localised maintenance, modification and repair work without plugging productive pipes – or shutting down your system.

5/8” – 2” Size Range

51.1 Bar / 741 psi Design Pressure

Horizontal Or Vertical Fitting

High-Integrity Leak-Free Seal

Intrinsically Safe User-friendly Design

Offtake, branch or bypass pipework, instrumentation lines or drain pipes are often tucked out of the way; restricting access, and frustrating efforts to stay on top of routine maintenance.

Many small diameter pipes also lack dedicated shut-off valves, which means that operators have traditionally been forced to shut down their entire system, or isolate a larger, productive pipeline to fix a problem or install an upgrade.

This is time-consuming, costly and wasteful which is why our in-house engineering team developed BI-STOP – a line plugging tool designed for small pipes up to 2" in diameter.

Designed to expedite routine maintenance and repair work, BI-STOP is reusable, quick to deploy, and provides the reliably high-integrity isolation needed to replace pipework, cap dead legs, add a valve or clear a blockage without halting production.

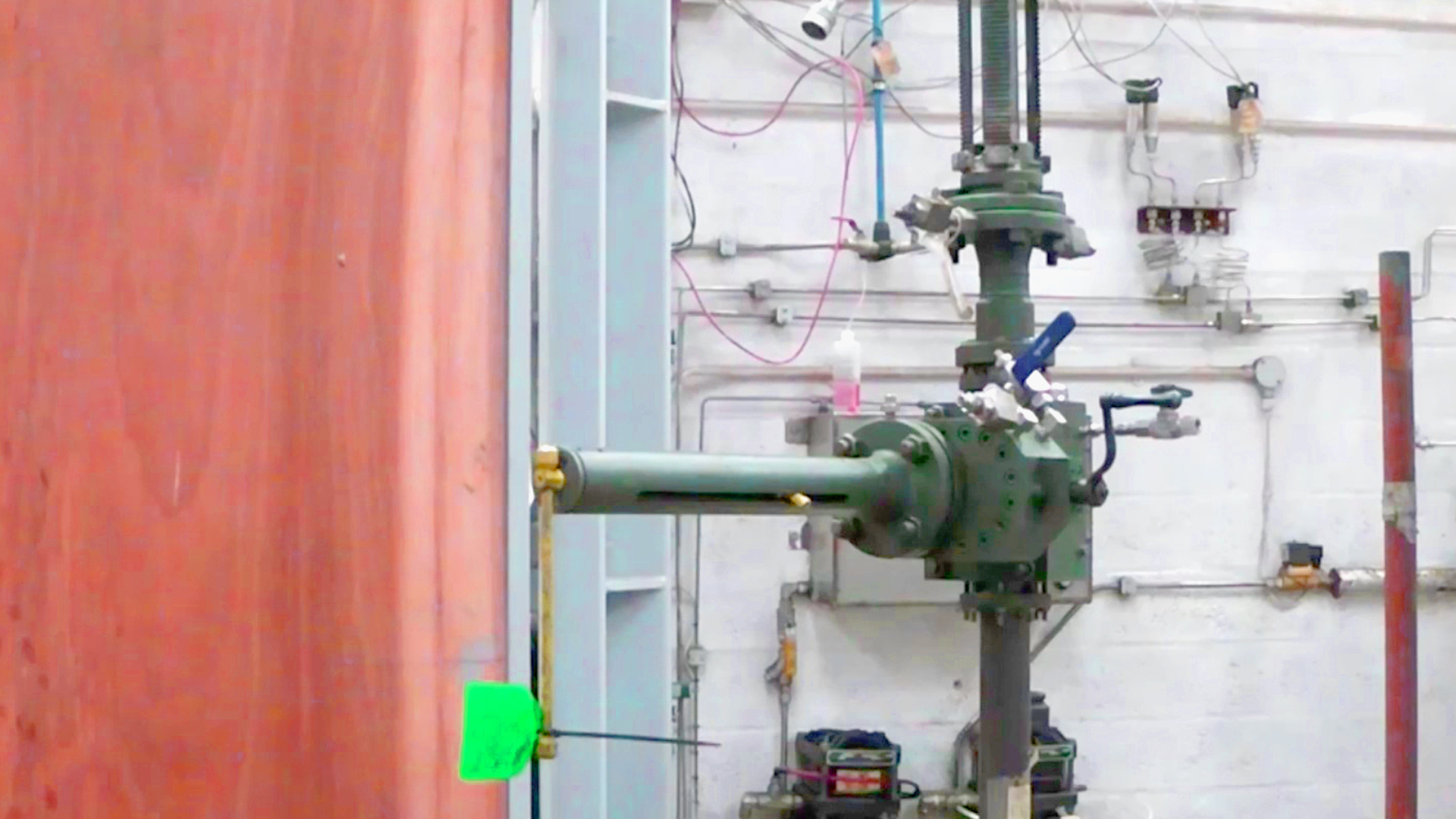

Case Study - 50 BI-STOP Tools Supplied To Major Canadian Utility Company

STATS Group built, tested and supplied 50 BI-STOP tools to ATCO – A Canadian utility company who needed a cost-effective solution for a major upgrade project.

Webinar - Pushing The Boundaries Of Pipeline Isolation

Learn about the latest developments in in-line isolation technology, and find out how to improve the safety and efficiency of maintenance operations in this 40 minute webinar.

The quality of the seals and the level of pipeline isolation provided by BI-STOP is such that the tool has also been used to install gas meters on live municipal pipelines in Canada, and completely re-route branch lines in numerous on and offshore facilities.

It simplifies work that's otherwise challenging or arduous to action, and significantly reduces routine or planned maintenance costs.

It's also a tool with a small footprint and low maintenance requirements, which means that it can be held in reserve for emergency situations – enabling clients to expedite repair work and minimise the costs associated with an unplanned outage.

Eliminate Hot Work Simplify Routine Repairs

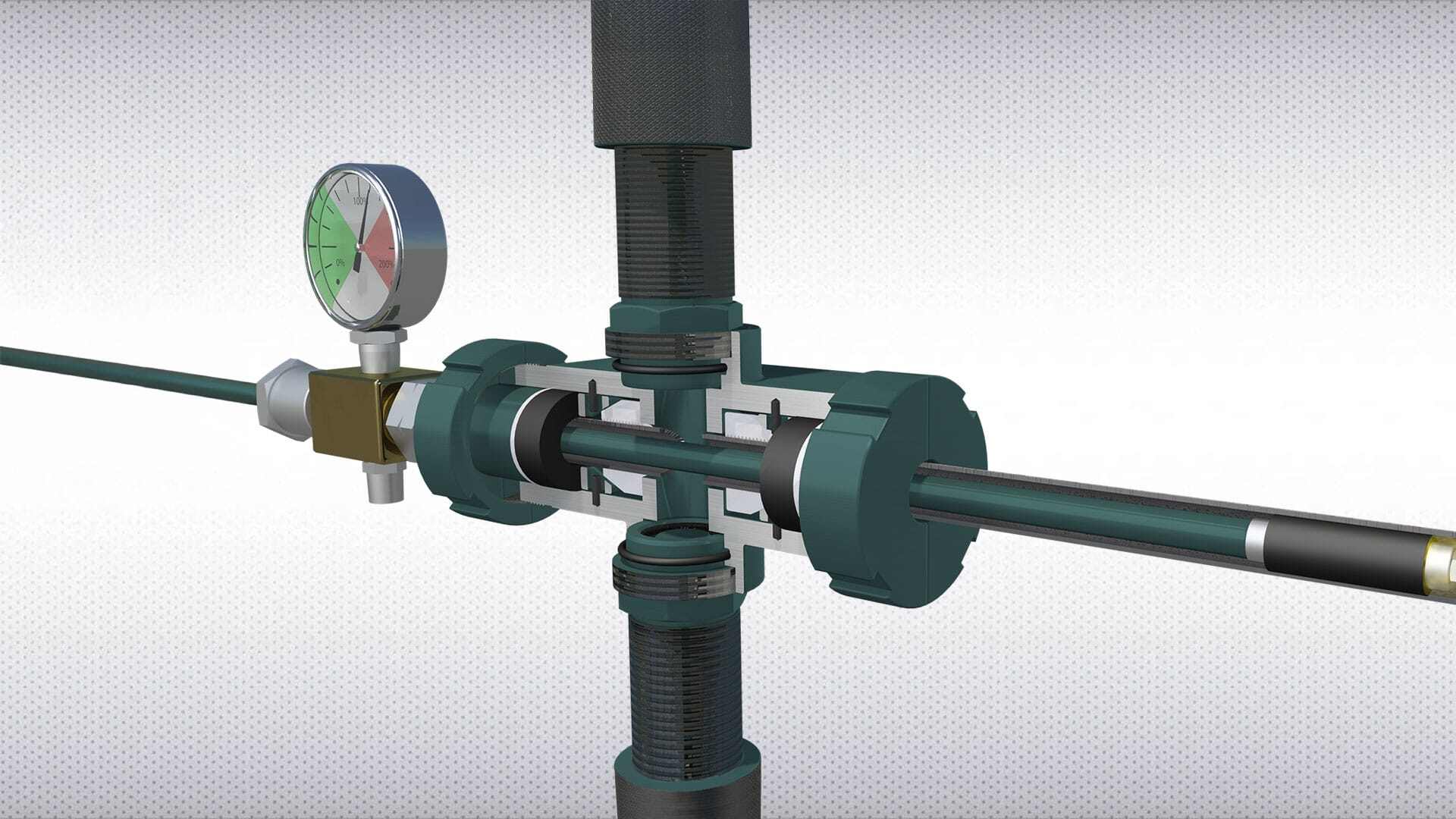

The patented BI-STOP provides a unique temporary line plugging system drawing on the same leak sealing advancements of our pipeline isolation technology.

Ensuring that the tool had a small footprint, without compromising its ability to take care of all pipe construct and destruct requirements (including proof testing), meant opting for a single seal design, but the seals themselves are made from a high-quality elastomer that delivers provable isolation on small bore, low-pressure pipes.

Our compact line plugging tool has a small footprint and takes care of all pipe construct and destruct requirements – including proof testing.

In simple terms, the tool gives operators an intrinsically safe and reliable compact pipe clamp, hot tap machine / drill and sealing element – ideal for quickly isolating a small pipe with minimal hassle, risk or disruption.

A typical use case might include replacing blocked instrumentation pipes or adding a new valve to an offtake or re-routing a branch without the need for a full or partial system shut down.

For example, a client recently discovered that a neglected bypass line had become blocked and corroded. The pipe in question was 3/4 inch in diameter, but without BI-STOP, the only way to replace it was to shut down production, depressurising the pipeline and carrying out the repair. This approach would be a long and expensive exercise.

We were able to deploy a team equipped with a BI-STOP, and successfully isolate the bypass while the main pipeline was still on-line and productive – completely eliminating the need for a planned outage, and slashing the costs associated with a simple pipe repair job.

There are other, more complex use cases too though. For example, STATS also supplied 50 BI-STOP systems to ATCO – A Canadian utility company who needed to simplify routine meter replacement jobs across the 300 Alberta communities they were responsible for.

Here, we built and tested the required units, put together comprehensive documentation and provided hands-on training. The client's operatives then carried out the upgrade work in six months; enabling them to expedite the project, and significantly reducing the costs associated with each isolation and upgrade.

Small-Bore Line Plugging Solution

Bi-Stop (MINI) Plugging Tool

An all-in-one tool designed to clamp, cut and isolate small-diameter pipe (5/8") with an industry-leading, high-integrity elastomer seal, BI-STOP (mini) enables operators to carry out routine or emergency maintenance without disrupting production or profitability.

Key Features

- Simple and straightforward to operate

- Can be deployed and activated in minutes

- Takes care of all pipe construct and destruct requirements

- Facilitates proof testing

- Durable elastomer seals with a long lifespan

- Provides leak-tight isolation in pitted or corroded pipework

- Suitable for all pipe materials and process flows

Bi-Stop Mini

BI-STOP (mini) has been developed for ease-of-use. It's a hand-operated tool that can be deployed in minutes, and enables maintenance teams to quickly isolate a pipe prior to testing and repair work.

In most cases, we deploy BI-STOP with trained and competent technicians – well-versed in our operating procedures, and experienced with small-bore pipe repair work. That said, we can and do supply individual or bulk BI-STOP orders to customers who want to carry out their own repair and maintenance work on small-diameter pipework.

In these scenarios, we also supply all of the written operating procedures and accompanying documentation needed to safely use our tool on live pipes. We can also provide in-person training to front-line operatives responsible for using our tool to ensure that all work is carried out properly and efficiently.

Irrespective of how you'll use BI-STOP, it's also helpful to know that STATS Group keep a large stock of all consumable parts, including hole saws and seals. Customers who maintain inventory of BI-STOP units on a contingency basis, or ask us to do the same enjoy better resilience against unplanned outages caused by issues with small-diameter pipe, and also report reduced maintenance costs.

Local Everywhere

Instead of flying people and equipment all over the world, we've set up fully-functional bases in nine strategic locations. These bases enable us to employ local technicians, work with local manufacturers, and invest in local economies. They're a significant investment, but our regional bases are key to delivering the best possible service for our clients - and minimising the environmental impact of our work.