A complete, fully compatible suite of products and services

Proven, fail-safe solutions for decommissioning projects

Decommissioning demands high-integrity isolation and long-term assurance.

STATS provides the field proven procedures, specialised tools and equipment, and experienced personnel to accomplish safe, compliant, and cost-effective abandonment that minimises environmental risks and any future liabilities your project demands.

DNV TYPE-APPROVED Solutions Certified to highest industry standards

VERIFIED Zero-Energy Zones Independently tested dual seal integrity

25-YEAR Design Life Permanent abandonment assurance

TURNKEY Delivery Complete end-to-end solutions

Decommissioning has marked a critical turning point for the oil and gas industry, as a growing number of aging wells and platforms reach the end of their operational life. This phase is not just a technical necessity, it’s one that’s environmentally and economically challenging.

Operators face a complex set of competing interests - balancing safety, cost, and environmental stewardship all within differing regulatory landscapes. Improper, incomplete or unverified decommissioning carries significant risks, including environmental damage, breaches of legal obligations, and exponentially increasing costs when things go wrong.

A key challenge in decommissioning is the safe removal of hydrocarbons from pipelines and topside assets. At the heart of this task lies high-integrity isolation, a critical barrier to ensure subsea pipelines can be safely flushed and decommissioned without the risk of repressurisation, flooding, or contaminating marine environments.

Without proven and effective isolation, there is a real and significant risk of hydrocarbon escape, posing severe environmental hazards and undermining the integrity of the entire operation. This necessity also extends to ensuring compliance with subsea isolation guidelines and providing safe conditions for personnel, particularly divers.

This is precisely where STATS Group excels, offering robust, proven solutions to help operators meet their regulatory and operational obligations. Globally recognised for expertise in pressurised pipeline isolation, mechanical connections, and abandonment plugs, STATS provides solutions that are DNV type-approved and engineered for fail-safe, double block pipeline isolation.

Case Study - Gulf of Mexico: 10" Pipeline Decommissioning

STATS deployed BISEP technology to isolate and abandon a subsea oil pipeline, flushing hydrocarbons through integrated ports to prevent environmental release while achieving verified zero-energy zone isolation.

Case Study - Dubai: 42" Subsea Abandonment Plug

Modified Tecno Plug provides permanent 25-year isolation for aging 1960s pipeline. Triple seal design with independent testing and mechanical locks ensures long-term abandonment assurance in critical subsea application.

Technologies like the BISEP® and Tecno Plug® create a verified zero-energy zone, where dual seals are independently tested and proven leak-tight before any intervention begins, ensuring a robust safety barrier for workers and the environment. This approach not only mitigates risk to personnel and the environment but also delivers significant time and cost savings for operators, often enabling work from topside rather than requiring expensive vessels or divers.

High-Integrity Decommissioning Solutions for a Secure Future

Our unwavering commitment to solutions with built-in engineering confidence, safety, and environmental responsibility is backed by our “right first time” philosophy, and underpinned by fully certified technologies.

With tools designed for a minimum 25-year design life and rigorous seal age testing, STATS' solutions provide the long-term assurance needed for permanent abandonment.

By investing in such innovative and certified solutions, operators can execute even the most complex decommissioning tasks safely, efficiently, and responsibly, preventing future issues and setting a new standard for asset management.

Decommissioning presents an inherently complex and challenging phase for operators, demanding meticulous planning and execution to manage environmental, safety, and economic risks. The safe removal of hydrocarbons and long-term abandonment of assets, particularly in live or critical systems, means that all solutions must provide absolute confidence and solid integrity. It’s about more than just abandoning a pipeline; it’s about providing a verified, fail-safe barrier that ensures compliance, protects the environment, and prevents future liabilities.

STATS Group is globally recognised for delivering precisely these high-integrity pipeline isolation and mechanical connection solutions.

Our commitment to getting it right the first time ensures operators can decommission with certainty, allowing them to truly "plug it and forget about it" for a secure future.

Our DNV type-approved Tecno Plugs provide double block and bleed isolation with a unique zero-energy zone, where both primary and secondary seals are independently tested and proven leak-tight. This allows critical work to proceed safely on pressurised pipelines, protecting both personnel and the marine environment.

For hot-tap deployed solutions, our patented BISEP offers significant safety advantages, allowing the isolated section to be flushed of hydrocarbons through an integrated port, preventing environmental release and reducing the need for additional fittings.

More than this, our weld-free SureConnect® mechanical connectors offer a safe, efficient, and permanent solution for end-capping redundant pipework or providing additional barriers behind valve structures. Engineered with dual independently activated seals and taper locks, they eliminate the risks of hyperbaric welding and provide long-term assurance.

Our comprehensive approach, from detailed engineering and collaborative discussions to rigorous testing and offshore execution, ensures that solutions are not only effective but also offer significant time and cost savings, often by enabling work from topside rather than requiring expensive vessels or divers.

Engineering confidence for aging asset retirement

Understanding the Risks

Decommissioning represents an inherently complex and challenging phase for operators, fraught with significant risks that extend far beyond mere technical execution. This critical turning point demands meticulous planning and robust execution to effectively manage environmental, safety, and economic risks. A primary and pervasive concern is the safe isolation and removal of hydrocarbons from aging pipelines and topside assets. Without proven, high-integrity isolation, there is a real and significant risk of repressurisation, flooding, or contaminating marine environments, posing severe environmental hazards and undermining the integrity of the entire operation.

Case Study: Zero Vessel Costs, Zero Delays. An Industry First

This industry-first platform deployment of an 8" tethered isolation plug enabled safe disconnection of a North Sea platform from live subsea infrastructure. The 80-metre deployment eliminated inter-operator dependencies, avoided vessel costs, and accelerated decommissioning by allowing platform removal to proceed independently of well abandonment schedules.

Mitigating Risk And Future Liabilities

- Eliminate repressurisation and marine contamination risks from unproven isolation methods

- Protect personnel and ensure diver safety through verified, compliant subsea isolation

- Avoid increased costs and future liabilities caused by inadequate decommissioning solutions

- Meet regulatory obligations while maintaining environmental stewardship

Abandonment: Pipeline End Plugs Diver or ROV Deployed

Delivering certainty in critical decommissioning operations

A Comprehensive Solution

STATS Group offers a comprehensive suite of robust, field proven solutions specifically engineered to navigate these complex decommissioning challenges and help operators meet their regulatory and operational obligations.

Our DNV type-approved Tecno Plugs provide fail-safe, double block pipeline isolation, creating a verified zero-energy zone that allows safe intervention on pressurised pipelines. Both primary and secondary seals are independently tested and proven leak-tight before any work begins, offering an unparalleled level of safety for personnel and the marine environment.

For hot-tap deployed applications, our patented BISEP tools offer significant safety advantages, including the unique ability to flush the isolated section of pipeline to remove hydrocarbons through an integrated port, preventing environmental release and reducing the need for additional fittings.

Certified Performance and Assurance

- DNV Type Approved Tecno Plugs provide fail-safe double block and bleed isolation with independently tested zero-energy zones

- Patented BISEP hot-tap technology flushes hydrocarbons through integrated ports, preventing environmental release and reducing additional fittings

- Weld-free SureConnect® mechanical connectors eliminate hyperbaric welding risks for permanent end-capping and barrier solutions

- Save on time and costs by enabling topside operations rather than requiring expensive vessels or divers

Beyond isolation, our weld-free SureConnect mechanical connectors provide a safe, efficient, and permanent solution for end-capping redundant pipework or adding critical barriers behind valve structures, eliminating the risks and complexities of hyperbaric welding.

This comprehensive approach, including services like subsea hot tapping for rerouting, is often delivered as a "turnkey" solution, minimising project complexity. Our innovative solutions also enable significant time and cost savings, often by performing work from topside rather than requiring expensive vessels or divers.

Subsea Remote Tecno Plug Fail-Safe Double Block Isolation

A proven approach to permanent abandonment

Right First Time - A Proven Process

Our approach to decommissioning is underpinned by a rigorous and proven process, designed to ensure complete confidence from initial concept through to permanent abandonment. It begins with detailed engineering studies and collaborative discussions with clients and partners, meticulously exploring, developing, and risk-assessing every element of the project.

Central to our methodology is the independent testing and verification of all isolation tools. Each BISEP and Tecno Plug undergoes a stringent test regime to confirm the integrity of both primary and secondary seals, ensuring the zero-energy zone is fully leak-tight before an Isolation Certificate is issued to all parties.

Engineered For Long-Term Integrity

- Independent testing and verification of all isolation tools, with Isolation Certificates issued after proving leak-tight integrity

- Full DNV certification to DNV-OS-F101 and DNV-RP-F113 standards, ensuring absolute compliance and reliability

- 25-year design life with extensive seal age testing provides long-term abandonment assurance

- Collaborative engineering approach from initial concept through detailed risk assessment to permanent abandonment

- "Plug it and forget about it" confidence minimises future failures and eliminates long-term liabilities

Our BISEP and Tecno Plug technology is fully certified to the highest industry standards, including DNV-OS-F101 for Submarine Pipeline Systems and DNV-RP-F113 for Subsea Pipeline Repair, providing absolute assurance of compliance and reliability.

Furthermore, our unwavering commitment to longevity is evident in the design: plugs are engineered for a minimum 25-year design life, backed by extensive seal age testing to guarantee long-term integrity, allowing operators to truly "plug it and forget about it" for a secure future.

A Responsible, Safe Legacy For Aging Assets

STATS Group’s "Right First Time" philosophy, dramatically minimises potential future failures, mitigates long-term liabilities, and ensures a responsible and safe legacy for aging assets.

48in Subsea BISEP, Middle East Fail-Safe Double Block & Bleed Isolation

Proven Technologies for Complete Decommissioning Solutions

STATS delivers comprehensive decommissioning projects using our integrated suite of field-proven technologies.

From high-integrity isolation and hot-tap deployment to mechanical connections and permanent abandonment, each tool is engineered to work seamlessly together, providing operators with turnkey solutions that minimise complexity, reduce costs, and ensure regulatory compliance.

Our DNV-certified products, combined with rigorous testing protocols and expert personnel, enable safe, efficient abandonment of aging assets while protecting personnel and the marine environment.

Subsea BISEP® Line Plugging Tool

The highest level of hot tap installed pipeline isolation for the subsea environment. With significant safety advantages over traditional line stop technologies, hydraulically activated dual seals provide leak-tight isolation of live, pressurised pipelines.

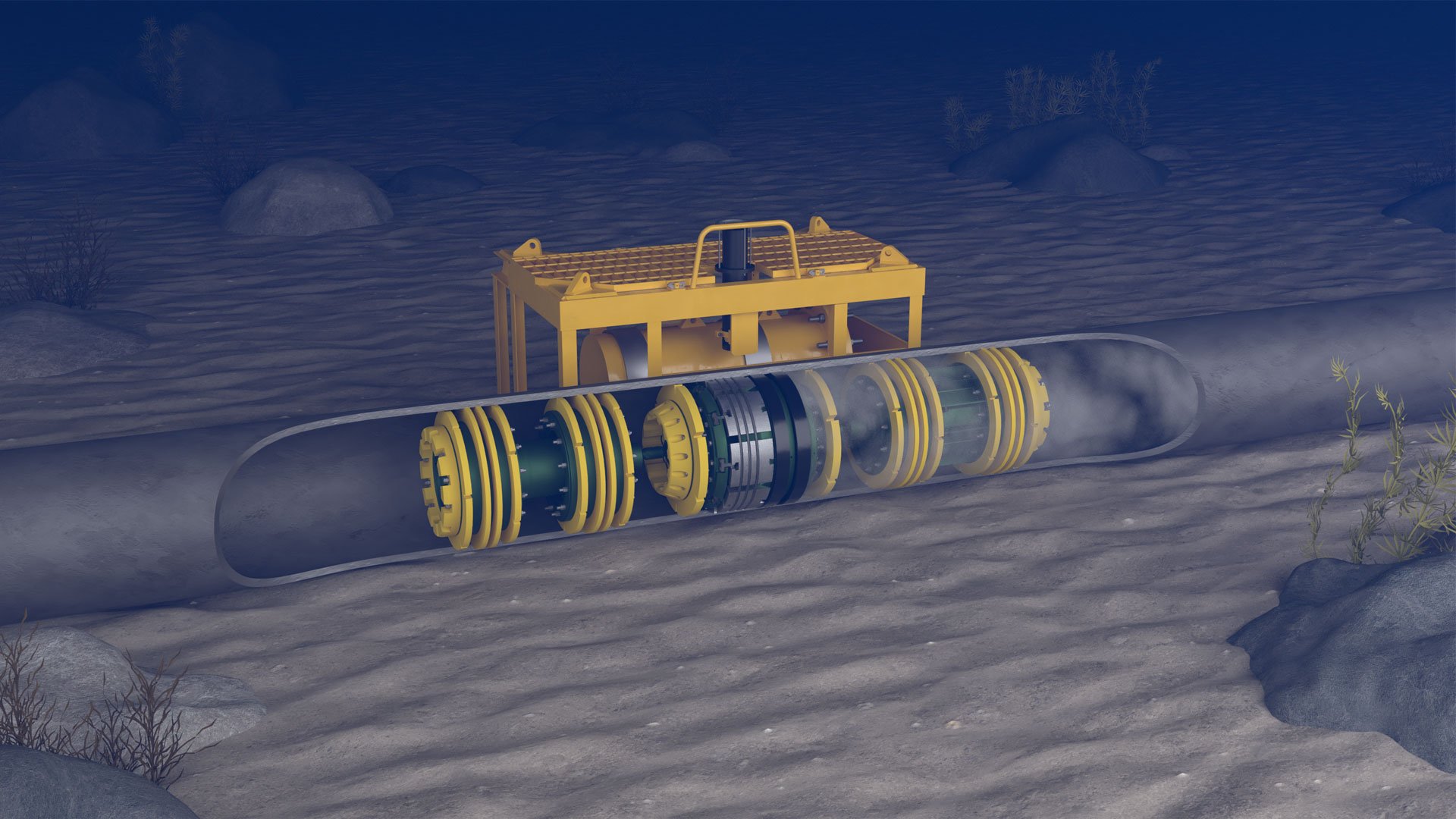

Subsea Remote Tecno Plug®

DNV Type Approved inline isolation tools providing fail-safe double block and bleed / monitored isolation of pressurised subsea pipelines. Tethered or remotely operated with independently tested dual seals creating a verified zero-energy zone. Essential for safe intervention and permanent abandonment applications.

Subsea Connectors

Weld-free mechanical connectors engineered for permanent end-capping of redundant pipework and adding critical barriers behind valve structures. Dual independently activated seals with taper locks eliminate hyperbaric welding risks, providing long-term assurance for decommissioning projects.

SureTap® Hot Tapping Machines

Field-proven hot tapping machines for subsea applications. For a reliable connection to existing piping or pressure vessels without interrupting operations or used as an access point for temporary BISEP line stopping. Small bore hot tapping can also be used to vent and purge abandoned pipelines prior to breaking containment.

Subsea Abandonment Plugs

Robust isolation barriers designed as temporary or permanent caps for open pipe ends. Prevent seawater ingress and residual hydrocarbon escape during abandonment operations. Engineered for long-term reliability in critical subsea decommissioning applications.

Local Everywhere

Instead of flying people and equipment all over the world, we've set up fully-functional bases in nine strategic locations. These bases enable us to employ local technicians, work with local manufacturers, and invest in local economies. They're a significant investment, but our regional bases are key to delivering the best possible service for our clients - and minimising the environmental impact of our work.