STATS Group has seen demand grow for their Tecno Plug® isolation services in the Asia Pacific region as they are ideally suited to enable pipeline operators to maintain existing pipeline networks and service developments that are under construction.

In addition to completing offshore and subsea pressurised isolations in Malaysia and the South China Sea in the last 12 months, STATS have also completed a number of onshore projects in New Zealand.

Recently STATS has completed three pressurised pipeline isolation projects on behalf of OSD Pty Limited for major operators, efficiently facilitating the safe replacement and installation of valves. Conventional repairs of this type would typically require the pipeline to be completely hydrocarbon-free by flaring the gas and nitrogen purging the entire length of pipeline to enable a safe intervention. The gas flaring and subsequent purging of the pipeline would add extensive operational and procedural requirements which have significant time, environmental and cost implications.

STATS piggable isolation tools are non-invasive and have advantages over traditional hot tap and line stop technologies as they require no welding or cutting into live lines and leave no residual fittings or holes in the pipeline.

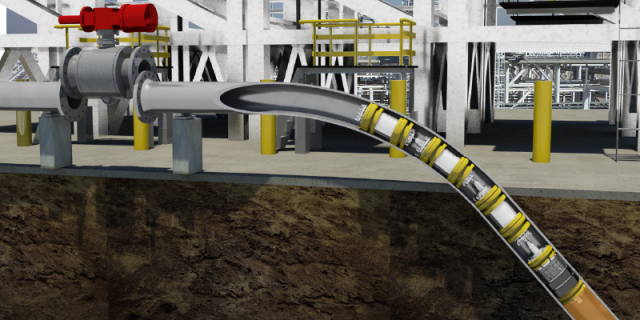

STATS high-pressure Tecno Plug isolation tools can be pigged or pushed to location and are hydraulically set to activate dual seals and locks, providing temporary isolation and allowing sections of pipework to be vented, creating safe worksite conditions for repair and maintenance to be carried out safely, often without affecting production.

Once the Tecno Plug is set, the dual seals are independently tested with full pipeline pressure in the correct direction, to confirm leak-tight isolation and allow the pipeline to be bled down to ambient at the rear of the Tecno Plug. The void between the Tecno Plug seals is vented to ambient to create a zero-energy zone, providing double block and bleed isolation.

Recent projects have included isolating a defective ESD valve on the land-based end of a pipeline delivering well stream products from an offshore platform to a major production facility. The 12” pipeline operating at 72 bar was unable to be depressurised, however, STATS’ remotely operated Tecno Plug provided the required double block and bleed isolation necessary to safely replace the valve. read the full case study

Remote Tecno Plug isolating 72 barg gas pipeline to allow ESDV changeout

Subsequent isolations have included isolating both ends of a 30” natural gas pipeline, to allow installation of new pigging launchers and receivers at either end of the pipeline.

On this occasion the remotely operated Tecno Plug was not suitable due to space limitation on the pipeline. However, STATS’ compact Tecno Plug design, houses both seals and locks on a single module, which provides the shortest isolation plug in market. This allowed the Tecno Plug to be deployed into the pipeline on a tether, further reducing the length of the plug and allowing the pipeline to be successfully isolated and allowing valves to be installed into the system without depressurising the entire pipeline.

A spokesperson for OSD, said: “OSD has a unique position within the Australasian pipeline integrity industry, having two members of our team that previously worked with this technology in the northern hemisphere. As a result, we have a sound understanding of this leading-edge technology, and can specify and facilitate applications that provide solutions to asset owners and operators in this region.”

In order to meet demand and effectively respond to the emerging opportunities, STATS has opened a sales and technical support office in Kuala Lumpur, Malaysia. Gareth Campbell, regional sales manager, based in Kuala Lumpur, said: “The market potential is massive and our DNV GL type approved intervention and isolation tools are unlike other options available in the market place, which gives us the confidence to make this investment and take a long-term approach to growth in this region.”

There is growing demand in region for STATS range of hot-work barriers and localised hydrostatic testing services. These tools enable pressure testing of new welds and fittings during planned maintenance shutdowns.

STATS has supplied one of Australia’s largest oil and gas operators with hydraulically activated In-Line Weld Test Tools, ranging in size from 10” to 40” and including technicians during each of the shutdowns. In addition to the standard dual seal design of the In-Line Weld Test Tool, STATS has also provided positive isolation barriers that include locks for use in ambient pipelines where there is the potential for pressure to build up in the system.

STATS Group process plant solutions manager, Sandy Peter, said: “Our In-Line Weld Test Tools are deployed in to ambient pipework to provide a verified vapour barrier, allowing hot work to be safely and efficiently performed without the risk to personnel from the migration of flammable or harmful vapours. The same tool is then utilised to verify the integrity (hydro test) of the new weld or fitting.”

The Operator’s safety philosophy required a dual positive isolation before conducting any hot work activities. Traditionally, this means attaching blind flanges at multiple locations for every field weld and carrying out a system hydro test to prove the integrity of the new welds. STATS’ range of dual sealed test tools negate the need to flood and dewater large piping systems, enhancing safety and saving time and resources.