Case Study

12” Remote Tecno Plug, Valve Changeout, Malaysia

STATS Group was contracted on behalf of E&P O&M Services Sdn Bhd (EPOMS) to provide isolation and reinstatement leak-testing of a 12” shutdown valve on the Larut A platform, offshore Malaysia.

STATS supplied a DNV type approved Remote Tecno Plug® to provide a fully monitored, leak-tight dual seal isolation of the pressurised oil export pipeline, providing safe worksite conditions to allow the shutdown valve to be removed and replaced.

A site survey and gauge pigging run was conducted at the Larut A platform to gather information critical for the successful deployment and pigging of the Remote Tecno Plug. Prior to deployment of equipment to the platform a full Factory Acceptance Test (FAT) was performed in a purpose-built test-fixture, fabricated to simulate the client pipeline configuration. Upon successful completion and independent witnessing of all FAT operations the equipment was mobilised to the platform.

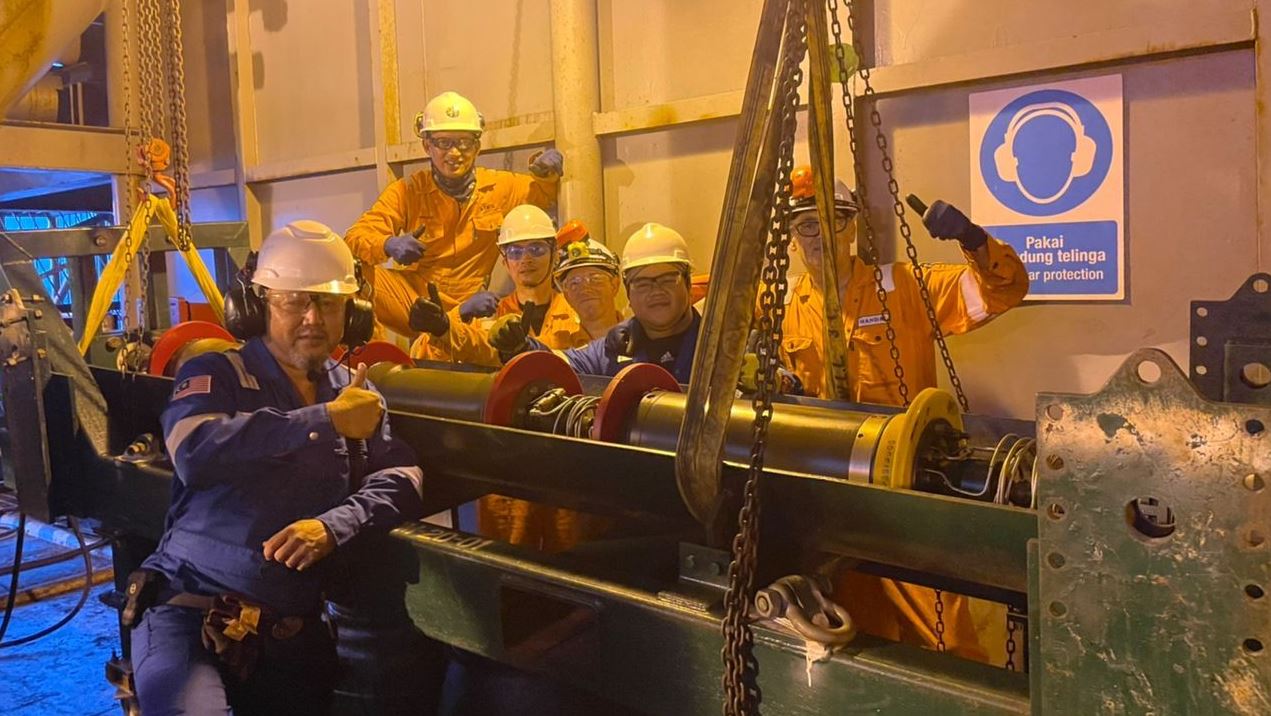

Once onsite the pig launcher was drained, vented and purged to allow the isolation plug to be loaded into the launcher. The Tecno Plug was pigged with water and constantly tracked 15 metres around a 5D bend and passed the Shutdown Valve. Pigging was halted once the Tecno Plug reached the exact isolation location and the plug was hydraulically activated to engage the locks and dual seals against the pipe wall.

Communication was achieved using an extremely low frequency inductive system which sets and monitors the Tecno Plug throughout the isolation. As part of the isolation barrier proving sequence, each seal was tested independently with full pipeline pressure in the direction of the expected pressure differential, proving both seals of the double block isolation are leak-tight. The annulus between the Remote Tecno Plug seals was then vented to ambient to create a zero-energy zone. With the pipeline vented behind the Tecno Plug an ‘Isolation Certificate’ was then issued to the client.

With the 20 bar isolation of the pressurised export pipeline in place and the double block and monitored isolation verified the valve replacement workscope was safely conducted. The Tecno Plug was constantly monitored and remained stable for the full six-day isolation period. Once completed a reinstatement leak-test of the new SDV was then conducted against the rear of the Tecno Plug while the isolation was remined undisturbed.

Upon completion of the reinstatement leak-test, the pipeline pressure was equalised allowing the Remote Tecno Plugs to be hydraulically unset and pigged back to the launcher.

A spokesperson for EPOMS said: “The use of the Remote Tecno Plug allowed the SDV to be safely replaced without the need to drain or water flood the export pipeline. Compared to the conventional method of water flooding which required a minimum 10-day preparation, the valve replacement activities were completed within 6 days and reduced the number of personnel required to complete the operation”.

Gareth Campbell, Regional Manager for Asia Pacific at STATS Group, said: “The isolation scope was completed as planned and incident-free which is testament to the teamwork and good communication between all parties. The use of the Remote Tecno Plug enabled the valve replacement to be completed efficiently, significantly reducing the platform shutdown compared to conventional methods.”