Case Study

24” Remote Tecno Plug, Pipeline Relocation, Canada

Tool - Tecno Plug Isolation Tool

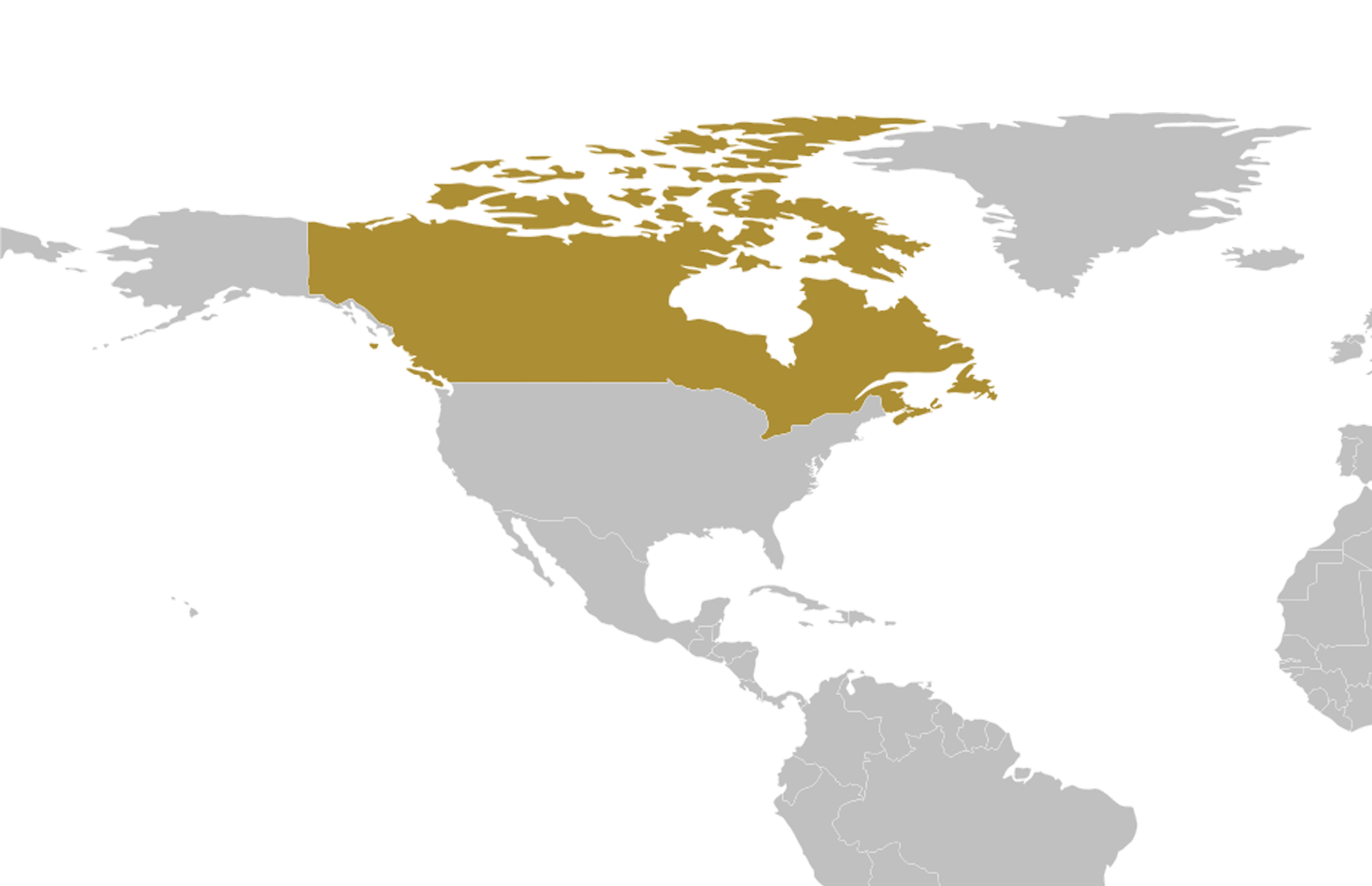

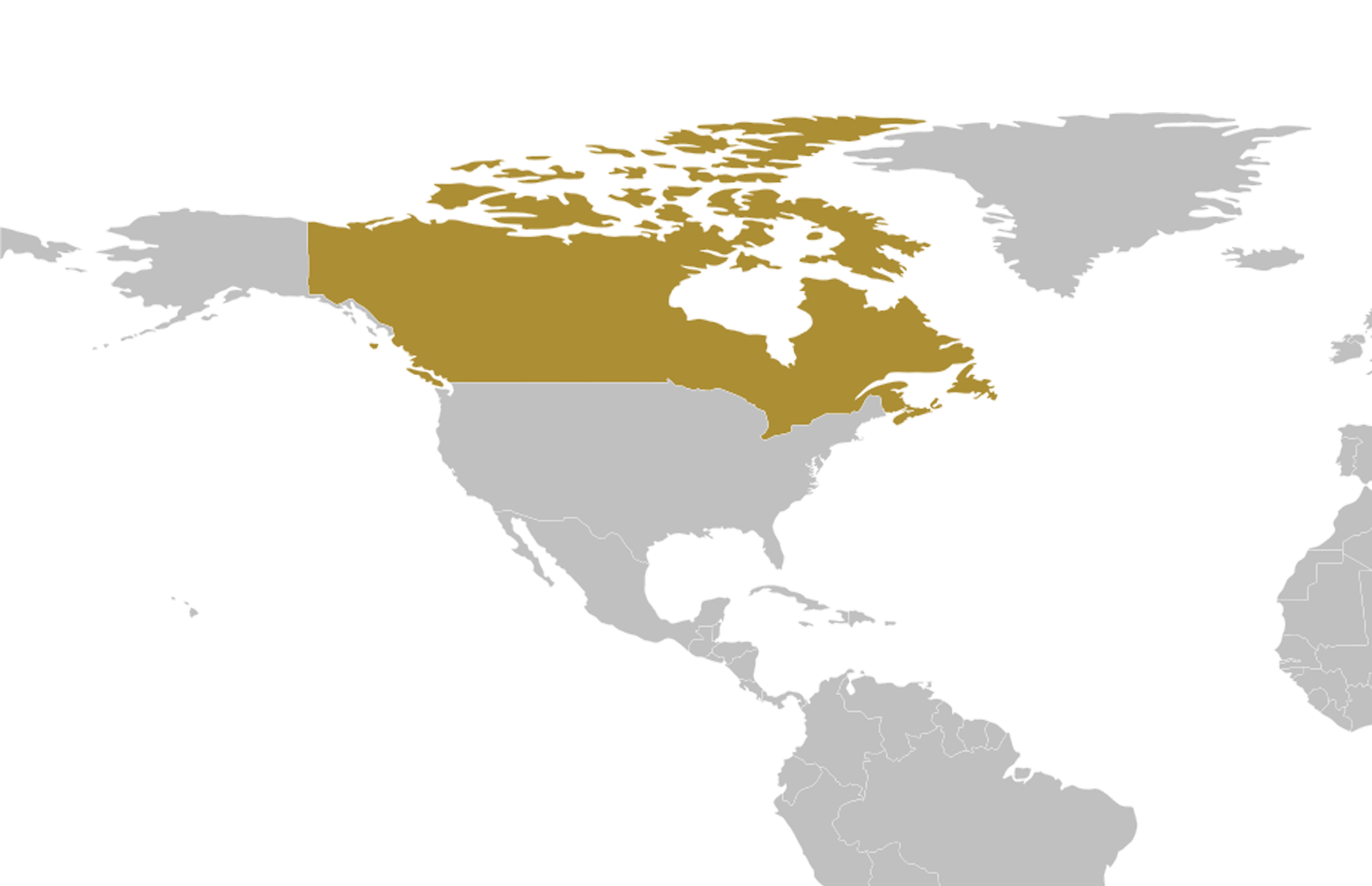

Location - Canada

STATS Group was recently contracted by a multinational pipeline company in Canada to provide leak-tight double block isolation of a 24” crude oil line that required to be re-routed due to terrain stability issues.

Data gathered from regular inline inspection (ILI) runs identified integrity issues and pipeline buckling due to ground movement where the buried pipeline travelled down a slope.

In order to restore integrity to the line a new section of pipeline was laid avoiding the affected area and once the pipeline was isolated, purged and vented, the damaged section was cut out and the new section was safely welded and tied in.

A Challenging 64-Mile Pigging Operation - and a Tight Shutdown Window

This was a complex and challenging project requiring the isolation plug to be pigged 64 miles, continually tracked and accurately positioned at the isolation location in order for the tie-in hot works to be completed within a 48 hour shutdown.

Tecno Plug - RTP Isolation

Pre-Project Engineering and Feasibility Study determines Best Approach

In order to fully assess the pipeline isolation project, an engineering and feasibility study was conducted to determine the safest and most efficient method of carrying out the isolation.

Following the study, STATS proposed the use of a Remote Tecno Plug®, a piggable inline isolation tool which provides fail-safe double block isolation of pressurised pipelines while the system remains live and at operating pressure.

The Remote Tecno Plug was chosen to provide the isolation over a traditional line stop method as it significantly reduced the number of fittings that would be left on the pipeline, therefore reducing potential future integrity issues and limiting the amount of equipment that would be required onsite.

With the Remote Tecno Plug and technicians at the worksite, final pre-deployment checks were conducted on the isolation plug before it was loaded into the pipeline launcher.

Positioning the Plugs at the Isolation Location

The Tecno Plug was installed into the launcher with two purge pigs at the front and two line fill plugs behind. The plugs were pigged through the pipeline to the isolation location with 90 metres of product between them. The plugs were constantly monitored and tracked through the pipeline to ensure accurate positioning of the plugs at the isolation location and a pre-installed nitrogen inject point to vent and purge the pipeline.

24in RTP, Crude Oil Pipeline Re-route

Isolation Barrier Proving - Testing and Isolation Certification

Once at location, the Remote Tecno Plug was hydraulically activated to engage the locks and dual seals. As part of the isolation barrier proving sequence, each seal was tested independently with full pipeline pressure in the direction of the expected pressure differential, proving both seals of the double block isolation were leak-tight. The annulus between the Remote Tecno Plug seals was then vented to ambient to create a zero-energy zone and an isolation certificate was issued the client.

The workscope was completed safely in just 30 hours, providing the client with significant savings, and returning the pipeline to production ahead of schedule. The successful delivery of the project is testament to the teamwork and good communication between all parties.

Wes Gardner

Tie-In Operations and Isolation Removal

With the isolation in place, the remaining line was blown down by pumping nitrogen into the pipeline through an injection point behind the isolation plug and pigging the purge pigs to the terminal receiver. Following the purging activities the affected section of pipeline was cut and the new pipeline was welded into place while the pipeline remained pressurized at 330psi.

With the tie-in operations completed, the purge pigs were pigged with product from the terminal receiver towards the set Remote Tecno Plug displacing the nitrogen in the pipeline and equalizing the pressure in the pipeline. The Remote Tecno Plug was then unset, removing the isolation and all five pigs were pigged through the new section of pipeline to the terminal receiver.

Pipeline returned to production ahead of schedule