Case Study

STATS Group Delivers Landmark First Hot Tap & BISEP® Isolation Project in Indonesia

Tool - BISEP Plugging Tool, SureTap Hot Tap Machine

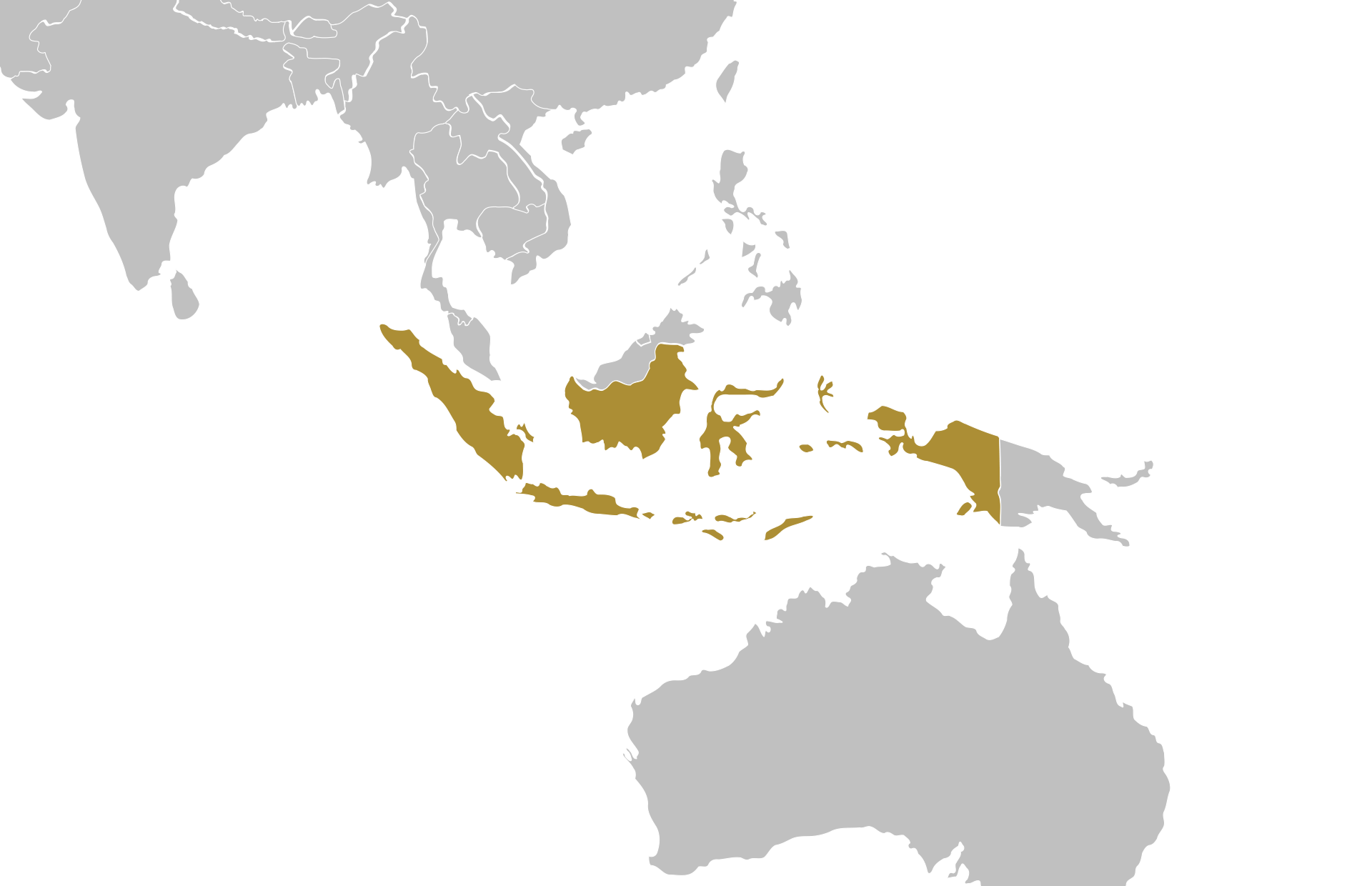

Location - Indonesia

.jpg?width=1600&height=1200&name=PHOTO-2025-05-13-14-36-29%20(4).jpg)

STATS Group has successfully completed its first ever hot tap and BISEP® isolation project in Indonesia to support PEGASOL on behalf of Pertamina Gas Negara (PGN).

STATS executed 12 precision hot tap operations across three challenging locations in a single campaign, the scope included six 16” high pressure hot taps to deploy BISEP isolations, along with 16” hot taps for a new permanent bypass.

The project had been on hold since 2017 as PGN was unable to find a suitable solution. That changed when STATS introduced its market leading technology, enabling the seamless re-routing of permanent pipeline sections without any shutdown or disruption to gas supply.

The client selected STATS hot tap installed BISEP technology to provide a fail-safe double block and bleed isolation, delivering leak-tight isolation to safeguard personnel and the environment compared to lip seal isolation technology previously used by the client. Multiple BISEPs were used to provide mid-line isolation of pipeline sections and the introduction of a bypass line allowed sectional isolation to take place without the need to shut down the entire system or affect product flow.

The project commenced by excavating the 16” pipeline at the three isolation locations allowing four split-tee fittings to be welded onto the pipeline at each location. Six fittings provided full bore access for the BISEP line stop tools and the other six fittings provided connection points for the permanent bypass pipeline that maintained the supply of gas while the scope was carried out.

Once all fittings had been welded to the pipeline and tested, valves were attached to each of the fittings and hot tapping operations successfully performed. Following the completion of the hot tapping, the 16” bypass pipework was installed and tested, ready for the BISEP launchers to be fitted to the remaining six valves.

With the bypass valves open STATS’ patented BISEP temporary line plugging tools were deployed into the flowing pipeline and hydraulically activated to provide fail-safe double block and bleed isolation, with flow diverted via the bypass lines.

The hydraulically activated dual seals of the BISEP provide fully proven and monitored isolation of the pipeline inventory throughout the entire project. Due to the leak-tight seals the isolation does not require any additional equalisation or bleed valves to be installed on the pipeline.

Each BISEP was then subject to a test regime to independently verify both the primary and secondary seals under full pipeline pressure. The cavity between the seals (annulus) was vented to ambient and verified as a zero-energy zone, ensuring a proven double block and bleed isolation. Once the test regime was completed, an Isolation Certificate was issued to notify all parties of the safe isolation of the pipe sections.

Utilising integrated offtakes on the BISEP launcher, nitrogen was injected into the isolated pipeline between the set BISEPs to purge and depressurise the pipeline prior to cutting and removing the required section. This unique feature is exclusive to the BISEP and not possible when using conventional lip seal line stopping equipment.

On completion of a successful reinstatement test of the pipelines, the BISEPs were hydraulically unset and retracted back into the launchers.

With all slab valves closed the BISEPs were removed and the hot tap machine was used to deploy completion plugs into the fitting offtake flanges. Once the completion plugs had been deployed and activated in the off-take flanges, the hot tap machine and valves were removed from the pipeline and blind flanges bolted in place.

One of the key challenges presented during this project was the continuous rainfall which caused site flooding after the overnight failure of dewatering pumps. The scope was further complicated due to complex rigging requirements stemming from underground pipeline depth and demanding site conditions, including 45° inclined sections of the pipeline. The hydraulic deployment of the BISEP allows for deployment into angled or sloping pipelines, something not possible with traditional gravity deployed line stopping equipment. Despite these obstacles, STATS’ team demonstrated both the resilience of their equipment and depth of their expertise, completing the work safely, efficiently and to the highest standard.

Executing 12 hot taps, 6 BISEP isolations, and 6 completion plugs in a single campaign especially on underground and inclined pipelines are no small feat, particularly on a live 16” high-pressure gas line. The BISEP® system provided proven double block and bleed isolation throughout, giving our client the confidence to proceed safely in some of the most challenging site conditions. This project shows the robustness of our technology and the capability of our team to deliver complex pipeline interventions safely and efficiently.

Ragesh Ravi

This landmark achievement for STATS has not only proven the capability of our technology in Indonesia but also sets a new benchmark for high integrity, leak-tight pipeline intervention and isolation solutions across Asia Pacific. The project provided an efficient, commercially significant solution for the client, allowing them to successfully divert their pipeline away from privately owned land. With BISEP® providing assured isolation, our client saw first-hand the value of deploying advanced solutions that safeguard people, assets, and production.

Gareth Campbell