Engineering Excellence: How STATS Enabled OQGN's Critical Pipeline Tie-In, Oman

The Sultanate of Oman boasts an extensive oil and gas pipeline infrastructure, this network forms the backbone of the nation’s energy sector, driving economic growth and ...

Read the case study

-1.jpg?width=768&name=PHOTO-2025-05-13-14-36-29%20(4)-1.jpg)

STATS Group Delivers Landmark First Hot Tap & BISEP Isolation Project in Indonesia

STATS Group has successfully completed its first ever hot tap and BISEP® isolation project in Indonesia to support PEGASOL on behalf of Pertamina Gas Negara (PGN).

Read the case study

Executing Critical Valve Replacement on a 56” Pig Trap Receiver Without Halting Production, Saudi Arabia

STATS Group has successfully completed a 56” inline isolation of a crude oil pipeline in Saudi Arabia to enable a pig trap valve replacement without halting production.

Read the case study

Production Maintained During Challenging Valve Replacement, UK

STATS has successfully completed a challenging hot tap and line stop isolation on a 33bar operating system, allowing for the safe replacement of two 6" Slam Shut valves ...

Read the case study

In-Line Weld Test Tool reduces costs and saves time by providing localised hydrostatic testing of externally welded thrust rings

STATS In-Line Weld Test Tool reduces costs and saves time by providing localised hydrostatic testing of externally welded thrust rings.

Read the case study

Delivering Safe In-Line Isolation for Critical Valve Replacement, North Sea

STATS Group proudly supported a multi-party operation delivering high-integrity pipeline isolation services on a North Sea gas pipeline, ensuring safe access for an ...

Read the case study

-1.png?width=768&name=8in%20Structural%20Repair%20Clamp,%20Super%20Duplex,%20222%20bar,%20Shell,%20Nelson%20Platform,%20UKCS%20(4)-1.png)

Super Duplex High Pressure 8" Structural Repair Clamps, North Sea

STATS has successfully designed a bespoke engineered solution for a valued client to be installed offshore in the North Sea.

Read the case study

Precision Pipeline Intervention Enables Seamless Gas Segregation, Oman

STATS Group was contracted to perform hot tapping and line stopping operations for OQ Gas Networks (OQGN) on their 48” gas pipeline in Sur, Sultanate of Oman.

Read the case study

Long Distance Deployment of 30" In-Line Weld Test Tool, Scotland

STATS Group has successfully completed the long-distance deployment of a 30" In-Line Weld Test Tool at a gas processing terminal in Scotland.

Read the case study

.jpg?width=768&name=24in%20Extended%20Test%20Tool%20(2).jpg)

6" to 36" Extended Body Weld Test Tools, France

Patriot International approached STATS Group to provide a range of modified weld test tools from 6" to 36" for an extended period for a pipeline construction project in ...

Read the case study

4" Hot Tap And Line Stop Project For Oil Flowline Recommissioning Project

A challenging remote location at high altitude in the southern highland mountains of Papua New Guinea was the destination for STATS Group’s 4” Hot Tap and Line Stop ...

Read the case study

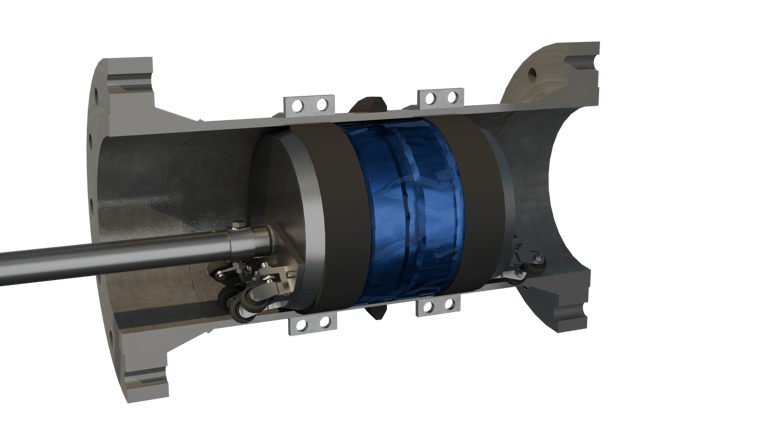

20” Tethered Tecno Plug, Main Oil Line Nahada to Mina Al Fahal, Oman

Petroleum Development Oman (PDO) had a requirement to remove 14 bends from 20” bypass pipework around block valves on their main oil pipeline while the line remained ...

Read the case study